RX10T Tungsten Flat Bar Ultra Fine Grain Size Fit Iron Finishing / Ceramic

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Usage: | Wood Cutting | Size: | Customized |

|---|---|---|---|

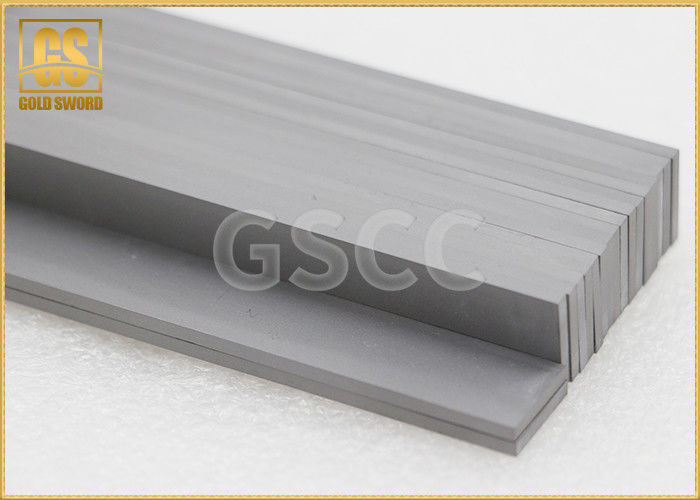

| Color: | Grey | Product Name: | Cemented Carbide Strips |

| Grade: | YG6X ZK30UF ZK30SF Etc | ||

| Highlight: | tungsten flat bar,rectangular carbide blanks |

||

Product Description

Tungsten Carbide Strips High Wear Resistant carbide Bars have

high hard ness, wear-resistance, and resistance to bending,for cutting general wood or hard wood ,used for processing blades, wear resistance parts etc.

It is widely used in military and aerospace. In the fields of machining, metallurgy, oil drilling, mining tools, electronic communication, construction, etc., with the development of downstream industries, the demand for hard alloys is increasing. And the future of high-tech weaponry equipment manufacturing, advances in cutting-edge science and technology, and the rapid development of nuclear energy will greatly increase the demand for high-tech content and high-quality stability of cemented carbide products.

| GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

| TPYE | SPECIFICATION | ||

| T(mm) | W(mm) | L(mm) | |

| STB424 | 3.2 | 19.1 | 152.4 |

| STB428 | 3.2 | 22.2 | 152.4 |

| STB432 | 3.2 | 25.4 | 152.4 |

| STB436 | 3.2 | 28.7 | 152.4 |

| STB440 | 3.2 | 31.8 | 152.4 |

| STB448 | 3.2 | 38.1 | 152.4 |

| STB46 | 3.2 | 4.8 | 152.4 |

| STB48A | 3.2 | 6.4 | 25.4 |

| STB48B | 3.2 | 6.4 | 31.8 |

| STB48C | 3.2 | 6.4 | 57.2 |

| STB48D | 3.2 | 6.4 | 76.2 |

| STB48E | 3.2 | 6.4 | 152.4 |

| STB510 | 4.0 | 7.9 | 152.4 |

| STB512 | 4.0 | 9.5 | 152.4 |

| STB516 | 4.0 | 12.7 | 152.4 |

| STB520 | 4.0 | 15.9 | 152.4 |

| STB524 | 4.0 | 19.1 | 152.4 |

| STB528 | 4.0 | 22.2 | 152.4 |

| STB532 | 4.0 | 25.4 | 152.4 |

| STB536 | 4.0 | 28.7 | 152.4 |

| STB540 | 4.0 | 31.8 | 152.4 |

| STB610 | 4.8 | 7.9 | 152.4 |

| STB610A | 4.8 | 7.9 | 76.2 |

| STB612 | 4.8 | 9.5 | 152.4 |

| STB612A | 4.8 | 9.5 | 76.2 |

| STB616 | 4.8 | 12.7 | 152.4 |

| STB616A | 4.8 | 12.7 | 76.2 |

| STB620 | 4.8 | 15.9 | 152.4 |

| STB620A | 4.8 | 15.9 | 76.2 |

| STB624 | 4.8 | 19.1 | 152.4 |

| STB628 | 4.8 | 22.2 | 152.4 |

| STB632 | 4.8 | 25.4 | 152.4 |

| STB636 | 4.8 | 28.7 | 152.4 |

| STB640 | 4.8 | 31.8 | 152.4 |

| STB648 | 4.8 | 38.1 | 152.4 |

| STB68 | 4.8 | 6.4 | 152.4 |

| STB68A | 4.8 | 6.4 | 76.2 |

| STB812 | 6.4 | 9.5 | 152.4 |

| STB812A | 6.4 | 9.5 | 76.2 |

| STB816 | 6.4 | 12.7 | 152.4 |

| STB816A | 6.4 | 12.7 | 76.2 |

| STB820 | 6.4 | 15.9 | 152.4 |

| STB820A | 6.4 | 15.9 | 76.2 |

| STB824 | 6.4 | 19.1 | 152.4 |

| STB824A | 6.4 | 19.1 | 76.2 |

| STB828 | 6.4 | 22.2 | 152.4 |

| STB832 | 6.4 | 25.4 | 152.4 |

| STB836 | 6.4 | 28.7 | 152.4 |

| STB840 | 6.4 | 31.8 | 152.4 |

| STB848 | 6.4 | 38.1 |

152.4 |

| THICKNESS | WIDTH | LENGTH | |||

| Size | Tolerance | Size | Tolerance | Size | Tolerance |

| 1~3 | 0~+0.3 | 4~6 | 0~+0.2 | 5~30 | 0~+0.5 |

| 3~5 | 0~+0.4 | 6~10 | 0~+0.3 | 30~60 | 0~+1 |

| 5~8 | 0~+0.5 | 10~15 | 0~+0.4 | 60~100 | 0~+1.5 |

| 8~12 | 0~+0.8 | 15~20 | 0~+0.5 | 100-150 | 0~+2 |

| 12~15 | 0~+1 | 20~25 | 0~+0.8 | 150~200 | 0~+2.5 |

| >15 | 0~+1.2 | 25~30 | 0~+1 | 200~250 | 0~+3 |

| 30~40 | 0~+1.5 | 250~300 | 0~+4 | ||

| 40~50 | 0~+2 | 300~350 | 0~+5 | ||

| 50~80 | 0~+3 | 350~450 | 0~+8 | ||

| >80 | 0~+5 | >450 | 0~+10 | ||

| 1,The deformation amount of the plane of ordinary specifications is no more than 0.3mm, and that of the side is no more than 0.5mm | |||||

| 2,Thickness <2MM, width BBB 0 20MM, lateral deformation less than or equal to 1MM |

|||||

Common specification sheet

| (T) | (W) | (L) |

| mm | mm | mm |

| 1~3 | 3.5 | 50~320 |

| 1~4 | 4 | 50~320 |

| 1~5 | 5 | 50~320 |

| 1~6 | 6 | 50~320 |

| 1~7 | 7 | 50~320 |

| 1~8 | 8 | 50~320 |

| 1~9 | 9 | 50~320 |

| 1~10 | 10 | 50~320 |

| 1~11 | 11 | 50~320 |

| 1~12 | 12 | 50~320 |

| 1~13 | 13 | 50~320 |

| 1~14 | 14 | 50~320 |

| 1~15 | 15 | 50~320 |

| 1~16 | 16 | 50~320 |

| 1~17 | 17 | 50~320 |

| 1~18 | 18 | 50~320 |

| 1~18 | 19 | 50~320 |

| 1~18 | 20 | 50~320 |

Traditional tool grades and usage recommendations

| Iso classification grouping code | Mark |

Density g/cm³ |

Hardness HRA |

Bending strength ≥ MPa |

use |

| K01 | YD05 | 14.90 | 93.0 | 1600 | It is specially used for processing various nickel-based, cobalt-based, iron-based and tungsten carbide-containing self-fluxing spray alloy materials, and can also be used for the processing of hardened steel. |

| K05 | YG3X | 15.10 | 91.8 | 1600 | Suitable for finishing, fine boring of cast iron, non-ferrous metal, heat resistant alloy and titanium alloy. |

| K10 | YD101 | 14.95 | 92.1 | 2500 | It has excellent wear resistance and toughness. It is used for finishing and finishing of non-ferrous metals and cast irons, especially for the processing of aluminum and its alloys. Turning is suitable for medium and high speed, and medium speed is recommended for milling. |

| YG6X | 14.95 | 91.5 | 2300 | Suitable for finishing of cast iron, non-ferrous metals, heat-resistant alloys and titanium alloys. | |

| K20 | YD201 | 14.89 | 91.0 | 2500 | Suitable for roughing to semi-finishing of heat resistant alloys and titanium alloys, cast iron and aluminum alloys. |

| YG6 | 14.95 | 89.5 | 2000 | Suitable for semi-finishing and light-load roughing of cast iron, non-ferrous metals and their alloys, heat-resistant alloys, titanium alloys and non-metallic materials. | |

| YG8 | 14.75 | 89.0 | 2200 | It is suitable for roughing of cast iron, non-ferrous metals and their alloys, heat-resistant alloys and titanium alloys. It has high impact resistance and is suitable for continuous and interrupted cutting. | |

| M05 | YS8 | 13.90 | 92.5 | 1800 | It is suitable for the finishing of iron-based, nickel-based superalloys and high-strength steels. It is also suitable for the finishing of chilled cast iron, heat-resistant stainless steel, high-manganese steel, hardened steel and glass products. |

| M10 | YW1 | 13.0 | 91.5 | 1600 | Suitable for semi-finishing of stainless steel and common alloy steel. |

| YW3 | 12.9 | 92.0 | 1800 | Suitable for finishing and semi-finishing of stainless steel and common alloy steel. | |

| M20 | YS2T | 14.40 | 91.5 | 2500 | Suitable for finishing and semi-finishing of stainless steel and low alloy steels and iron-based alloys, as well as for integral milling of low alloy steels. |

| YW2 | 12.9 | 91.0 | 2000 | Suitable for finishing and semi-finishing and light-load roughing of stainless steel and alloy steel. | |

| M30 | YL10.2 | 14.50 | 92.0 | 2800 | Suitable for high temperature alloys, heat resistant alloys, titanium alloys, etc., especially for coarse and semi-finishing of aerospace materials, allowing intermittent turning with increased rake angle. |

| P10 | YC10 | 10.31 | 92.0 | 1600 | Suitable for finishing steel and cast steel, with cutting speed and low feed low depth. |

| P20 | YC201 | 11.79 | 91.8 | 1800 | Suitable for semi-finishing and light-load roughing of steel, cast iron and stainless steel, it is a universal mark with good applicability. |

| YS25 | 13.0 | 90.5 | 2200 | Specially used for rough milling of steel and cast steel. | |

| YT14 | 11.40 | 90.5 | 1800 | Specially used for semi-finishing of steel and cast steel. | |

| P30 | YT5 | 12.81 | 89.5 | 1900 | Specially used for heavy cutting of steel and cast steel, in the case of poor working conditions, roughingwith medium and low speed and large feed. |

| YC330S | 12.95 | 90.5 | 2200 | Specially used for milling of steel and cast steel, it has good toughness and good impact resistance, and is the preferred grade for gravity milling. | |

| P40 | YC45 | 12.75 | 90.0 | 2550 |

Suitable for gravity cutting of steel and cast steel, it can be used for large cutting, also for section milling. |