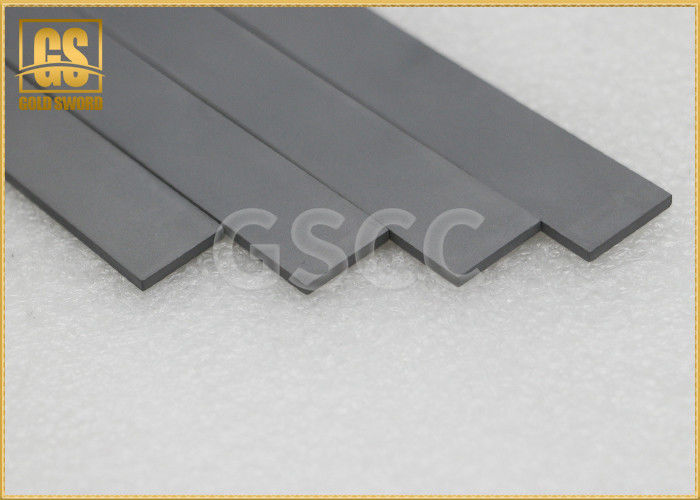

Multipurpose Carbide Wear Strips Non - Magnetic With Rough Grinding Surface

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Usage: | Wood Cutting | Size: | Customized |

|---|---|---|---|

| Color: | Grey | Product Name: | Cemented Carbide Strips |

| Grade: | YG6X ZK30UF ZK30SF Etc | ||

| High Light: | tungsten carbide square bar,tungsten flat bar |

||

Product Description

Traditional tool grades and usage recommendations

K01 It is specially used for processing various nickel-based, cobalt-based, iron-based and tungsten carbide-containing self-fluxing spray alloy materials, and can also be used for the processing of hardened steel.

K05 Suitable for finishing, fine boring of cast iron, non-ferrous metal, heat resistant alloy and titanium alloy.

K10 It has excellent wear resistance and toughness. It is used for finishing and finishing of non-ferrous metals and cast irons, especially for the processing of aluminum and its alloys. Turning is suitable for medium and high speed, and medium speed is recommended for milling.

YG6X Suitable for finishing of cast iron, non-ferrous metals, heat-resistant alloys and titanium alloys.

K20 Suitable for roughing to semi-finishing of heat resistant alloys and titanium alloys, cast iron and aluminum alloys.

Cemented carbide can also be used to make rock drilling tools, mining tools, drilling tools, measuring gages, wear parts, metal grinding tools, cylinder liners, precision bearings, nozzles, etc.

| TPYE | SPECIFICATION | ||

| T(mm) | W(mm) | L(mm) | |

| STB424 | 3.2 | 19.1 | 152.4 |

| STB428 | 3.2 | 22.2 | 152.4 |

| STB432 | 3.2 | 25.4 | 152.4 |

| STB436 | 3.2 | 28.7 | 152.4 |

| STB440 | 3.2 | 31.8 | 152.4 |

| STB448 | 3.2 | 38.1 | 152.4 |

| STB46 | 3.2 | 4.8 | 152.4 |

| STB48A | 3.2 | 6.4 | 25.4 |

| STB48B | 3.2 | 6.4 | 31.8 |

| STB48C | 3.2 | 6.4 | 57.2 |

| STB48D | 3.2 | 6.4 | 76.2 |

| STB48E | 3.2 | 6.4 | 152.4 |

| STB510 | 4.0 | 7.9 | 152.4 |

| STB512 | 4.0 | 9.5 | 152.4 |

| STB516 | 4.0 | 12.7 | 152.4 |

| STB520 | 4.0 | 15.9 | 152.4 |

| STB524 | 4.0 | 19.1 | 152.4 |

| STB528 | 4.0 | 22.2 | 152.4 |

| STB532 | 4.0 | 25.4 | 152.4 |

| STB536 | 4.0 | 28.7 | 152.4 |

| STB540 | 4.0 | 31.8 | 152.4 |

| STB610 | 4.8 | 7.9 | 152.4 |

| STB610A | 4.8 | 7.9 | 76.2 |

| STB612 | 4.8 | 9.5 | 152.4 |

| STB612A | 4.8 | 9.5 | 76.2 |

| STB616 | 4.8 | 12.7 | 152.4 |

| STB616A | 4.8 | 12.7 | 76.2 |

| STB620 | 4.8 | 15.9 | 152.4 |

| STB620A | 4.8 | 15.9 | 76.2 |

| STB624 | 4.8 | 19.1 | 152.4 |

| STB628 | 4.8 | 22.2 | 152.4 |

| STB632 | 4.8 | 25.4 | 152.4 |

| STB636 | 4.8 | 28.7 | 152.4 |

| STB640 | 4.8 | 31.8 | 152.4 |

| STB648 | 4.8 | 38.1 | 152.4 |

| STB68 | 4.8 | 6.4 | 152.4 |

| STB68A | 4.8 | 6.4 | 76.2 |

| STB812 | 6.4 | 9.5 | 152.4 |

| STB812A | 6.4 | 9.5 | 76.2 |

| STB816 | 6.4 | 12.7 | 152.4 |

| STB816A | 6.4 | 12.7 | 76.2 |

| STB820 | 6.4 | 15.9 | 152.4 |

| STB820A | 6.4 | 15.9 | 76.2 |

| STB824 | 6.4 | 19.1 | 152.4 |

| STB824A | 6.4 | 19.1 | 76.2 |

| STB828 | 6.4 | 22.2 | 152.4 |

| STB832 | 6.4 | 25.4 | 152.4 |

| STB836 | 6.4 | 28.7 | 152.4 |

| STB840 | 6.4 | 31.8 | 152.4 |

| STB848 | 6.4 | 38.1 |

152.4 |

Common specification sheet

| (T) | (W) | (L) |

| mm | mm | mm |

| 1~3 | 3.5 | 50~320 |

| 1~4 | 4 | 50~320 |

| 1~5 | 5 | 50~320 |

| 1~6 | 6 | 50~320 |

| 1~7 | 7 | 50~320 |

| 1~8 | 8 | 50~320 |

| 1~9 | 9 | 50~320 |

| 1~10 | 10 | 50~320 |

| 1~11 | 11 | 50~320 |

| 1~12 | 12 | 50~320 |

| 1~13 | 13 | 50~320 |

| 1~14 | 14 | 50~320 |

| 1~15 | 15 | 50~320 |

| 1~16 | 16 | 50~320 |

| 1~17 | 17 | 50~320 |

| 1~18 | 18 | 50~320 |

| 1~18 | 19 | 50~320 |

| 1~18 | 20 | 50~320 |

| (T) | (W) | (L) |

| mm | mm | mm |

| 1~18 | 21 | 50~320 |

| 1~18 | 22 | 50~320 |

| 1~18 | 24 | 50~320 |

| 1~18 | 25 | 50~320 |

| 1~18 | 26 | 50~320 |

| 1~18 | 28 | 50~320 |

| 1~18 | 30 | 50~320 |

| 1~18 | 32 | 50~320 |

| 1~18 | 35 | 50~320 |

| 1~18 | 40 | 50~320 |

| 1~18 | 30 | 50~320 |

| 1~18 | 32 | 50~320 |

| 1~18 | 35 | 50~320 |

| 1~18 | 40 | 50~320 |

| 1~18 | 45 | 50~320 |

| 1~18 | 50 | 50~320 |

| 1~18 | 55 | 50~320 |

| 1~18 | 60 | 50~320 |

Want to Know more details about this product