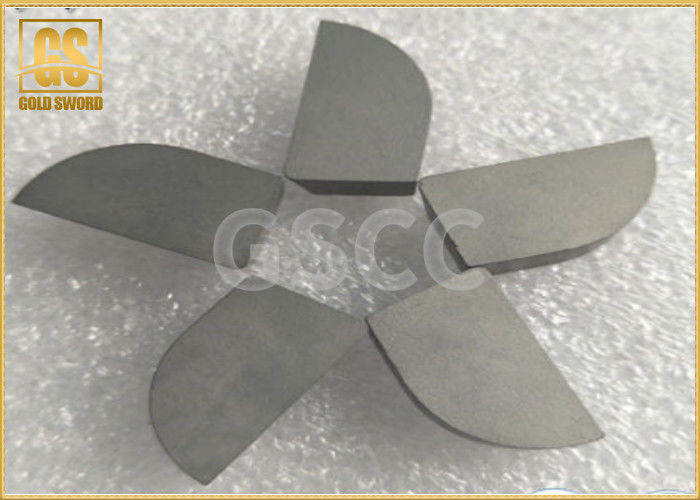

Strength Coal Drilling Tungsten Carbide Brazed Tips YW1 Long Life Span

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Size:: | Cusotmized | Application:: | Cutting And Processing |

|---|---|---|---|

| Material:: | Tungsten Carbide | Commodity Name:: | Cemented Carbide Products |

| Highlight: | tungsten carbide cutting tips,carbide brazing tips |

||

Product Description

GRADE Applications recommended

YG3:Suitable for finishing of cast iron and nonferrous metal.

YG6X:The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel.

YG6 / YG8: Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel.

YW1: Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel.

W2: The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs.

YT15: Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed.

YT14: Suitable for the finishing and semi-finishing of steel and cast steel.

YT5: Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions.

Advantage:

1. Over 10 Years' efforts in making high quality Hard Alloy Strips Blank and strips, Almost 8 years in doing importing and exporting business.

2. Rich experience in grade researching, mould designing, automatic press, HIP sintered, surface treating and quality control.

3. We have many years of experience in producing the tungsten carbide strips and have gained a wide reputation in the market . Welcome your inquiry anytime

| GRADE | ISO | HARDNESS | TRS | Applications recommended |

| GRADE | (HRA) | (N/mm2) | ||

| YG3 | K05 | 92 | 1400 | Suitable for finishing of cast iron and nonferrous metal. |

| YG6X | K10 | 91.5 | 1800 | The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

| YG6 | K15 | 90.5 | 1900 | Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YW1 | M10 | 91.6 | 1600 | Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

| W2 | M20 | 90.6 | 1800 | The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

| YT15 | P10 | 91.5 | 1600 | Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

| YT14 | P20 | 90.8 | 1700 | Suitable for the finishing and semi-finishing of steel and cast steel. |

| YT5 | P30 | 90.5 | 2200 | Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |