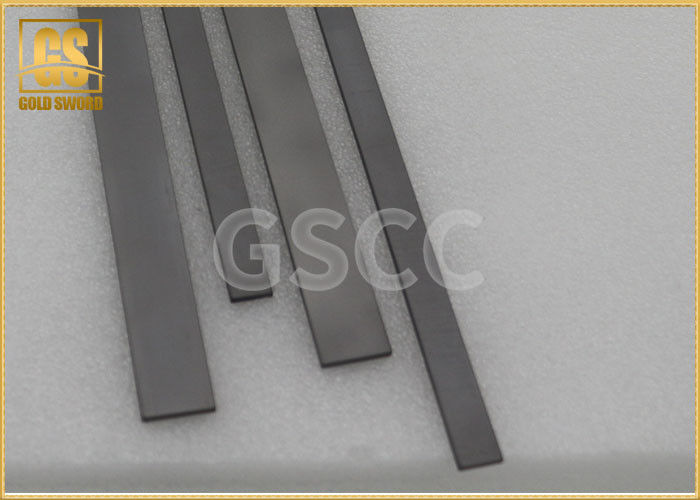

Powder Metallurgy Tungsten Carbide Blanks / Hard Tungsten Carbide Wear Parts

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Model Number: | Tungsten Carbide Blanks |

Payment & Shipping Terms:

| Minimum Order Quantity: | negotiate |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

| Supply Ability: | 80000 pcs per month |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Blanks | Application: | Powder Metallurgy |

|---|---|---|---|

| GS Grade: | RX10 / RX20 / RX10T / AB10 | Color:: | Gray |

| Size:: | Customized | Feature: | Hard |

| Highlight: | square carbide blanks,cemented tungsten carbide |

||

Product Description

Powder Metallurgy Tungsten Carbide Blanks / Hard Tungsten Carbide Wear Parts

Introduction of Tungsten Carbide Blanks

Tungsten Carbide Blanks is used as spare parts for agricultural machines.We offer a variety of tungsten carbide blades to meet specialized needs. Our nickel binder grades are idealfor the most demanding conditions in which corrosion, oxidation and wear push your tooling to the limit.Special shapes can be manufactured to client's specifications with appropriate grades, competitive pricing and prompt delivery.

Tungsten Carbide Blanks Advantages

1. made from 100% virgin raw material;

2. produced with advance equipments and process;

3. all products go through in-process and final inspection

| GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

Our Service

1,ISO , BV certificate and sound testing equipment to assure the quality

2,Professional advice for the application problems, we accept return of goods with quality problems or discuss

3,Survey Email of products usage will be sent timely to listen your feedback,our aim is trying to make everyone of our customers satified!

Our advantages:

1. Use 100% Raw material, strict incoming inspection.

2. Overpressure sintering, increasing the densification of the alloy teeth and increasing the 30% life span.

3. Can be customized according to the requirements of the customer.