Wear Resistant Tungsten Carbide Strips With 100% Original Tungsten Carbide Powder

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Model Number: | Tungsten Carbide Strips |

Payment & Shipping Terms:

| Minimum Order Quantity: | negotiate |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

| Supply Ability: | 80000 pcs per month |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Strips | Faeture: | Wear Resistant |

|---|---|---|---|

| GS Grade: | RX10 / RX20 / RX10T / AB10 | Color:: | Gray |

| Shape:: | Rectangle | Feature: | High Density |

| Highlight: | square carbide blanks,cemented tungsten carbide |

||

Product Description

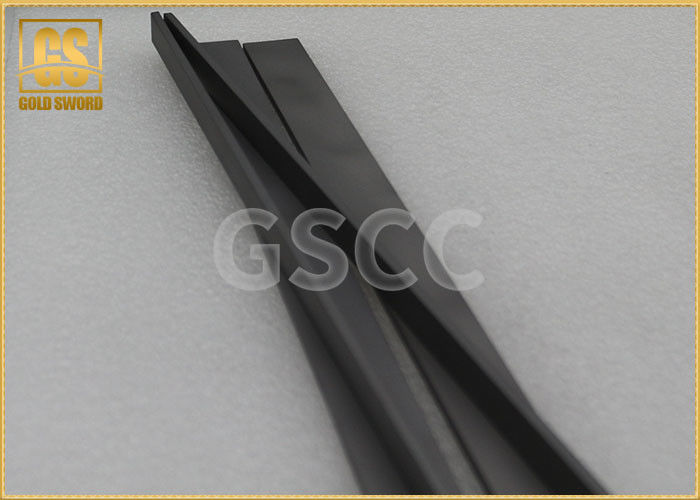

Wear Resistant Tungsten Carbide Strips With 100% Original Tungsten Carbide Powder

Introduction of Tungsten Carbide Strips

Tungsten Carbide Strips has good straightness, excellent hardness, and stable toughness. It offten applied to metal and steel cutting and machining process.

Tungsten Carbide Strips can be used for woodworking andcast iron cutting applications. It can be used in many field such as woodworking, machining of refractory alloys, stainless steel, high manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar, etc

Tungsten Carbide Strips can also be used for making the drill bits/ end-mills / reamers; automobile special cutters, printed circuit board special cutters, engine special cutters, horologe processing special cutters, integral vertical milling cutter, graver and etc. Besides, they can be also used for making of cemented carbide stamping head, core bar and perforation tools.

| GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse |

High toughness, difficult to break tooth. Special used for finger jointing tool. |

Note: Our company can produce alloy grades that are more suitable for special processing fields according to customer needs.

| TPYE | SPECIFICATION | ||

| T(mm) | W(mm) | L(mm) | |

| STB424 | 3.2 | 19.1 | 152.4 |

| STB428 | 3.2 | 22.2 | 152.4 |

| STB432 | 3.2 | 25.4 | 152.4 |

| STB436 | 3.2 | 28.7 | 152.4 |

| STB440 | 3.2 | 31.8 | 152.4 |

| STB448 | 3.2 | 38.1 | 152.4 |

| STB46 | 3.2 | 4.8 | 152.4 |

| STB48A | 3.2 | 6.4 | 25.4 |

| STB48B | 3.2 | 6.4 | 31.8 |

| STB48C | 3.2 | 6.4 | 57.2 |

| STB48D | 3.2 | 6.4 | 76.2 |

| STB48E | 3.2 | 6.4 | 152.4 |

| STB510 | 4.0 | 7.9 | 152.4 |

| STB512 | 4.0 | 9.5 | 152.4 |

| STB516 | 4.0 | 12.7 | 152.4 |

| STB520 | 4.0 | 15.9 | 152.4 |

| STB524 | 4.0 | 19.1 | 152.4 |

| STB528 | 4.0 | 22.2 | 152.4 |

| STB532 | 4.0 | 25.4 | 152.4 |

| STB536 | 4.0 | 28.7 | 152.4 |

| STB540 | 4.0 | 31.8 | 152.4 |

| STB610 | 4.8 | 7.9 | 152.4 |

| STB610A | 4.8 | 7.9 | 76.2 |

| STB612 | 4.8 | 9.5 | 152.4 |

| STB612A | 4.8 | 9.5 | 76.2 |

| STB616 | 4.8 | 12.7 | 152.4 |

| STB616A | 4.8 | 12.7 | 76.2 |

| STB620 | 4.8 | 15.9 | 152.4 |

| STB620A | 4.8 | 15.9 | 76.2 |

| STB624 | 4.8 | 19.1 | 152.4 |

| STB628 | 4.8 | 22.2 | 152.4 |

| STB632 | 4.8 | 25.4 | 152.4 |

| STB636 | 4.8 | 28.7 | 152.4 |

| STB640 | 4.8 | 31.8 | 152.4 |

| STB648 | 4.8 | 38.1 | 152.4 |

| STB68 | 4.8 | 6.4 | 152.4 |

| STB68A | 4.8 | 6.4 | 76.2 |

| STB812 | 6.4 | 9.5 | 152.4 |

| STB812A | 6.4 | 9.5 | 76.2 |

| STB816 | 6.4 | 12.7 | 152.4 |

| STB816A | 6.4 | 12.7 | 76.2 |

| STB820 | 6.4 | 15.9 | 152.4 |

| STB820A | 6.4 | 15.9 | 76.2 |

| STB824 | 6.4 | 19.1 | 152.4 |

| STB824A | 6.4 | 19.1 | 76.2 |

| STB828 | 6.4 | 22.2 | 152.4 |

| STB832 | 6.4 | 25.4 | 152.4 |

| STB836 | 6.4 | 28.7 | 152.4 |

| STB840 | 6.4 | 31.8 | 152.4 |

| STB848 | 6.4 | 38.1 | 152.4 |

Why choose us?

1. Strict quality control: all our cutting tools will be tested before shipping, the products you received are all with high quality.

2. Fast delivery: The normal and popular models are always in stock, shipment will be made very soon after you making payment.

3. Prompt response: Any of your inquiry to us, we will reply you within in 24 hours.

4. OEM & ODM accepted: We can produce tools as per your drawing.

5. Wide products ranges: Almost all kinds of cemented carbide products are in our supply scope, can meet your various needs from our one website.