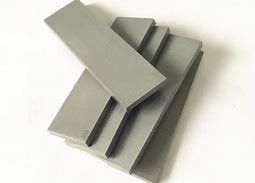

K30 K10 K40 Customised Tungsten Carbide Wear Plates With High Toughness

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Usage: | Cutting Tools, Woodworking, Metal Working | Name: | Tungsten Carbide Sheet |

|---|---|---|---|

| Application: | Small Inserts, Cutting Tips, Wear Parts | Size: | Customised |

| Highlight: | tungsten carbide wear plates,carbide plate stock |

||

Product Description

K30 K10 K40 Customised Tungsten Carbide Wear Plates With High Toughness

Carbide Wear Parts is a hard material composed of a metal matrix composite where carbide particles act as the aggregate and a metallic binder serves as the matrix. It is one of the most successful composite engineering materials ever produced. Its unique combination of strength, hardness and toughness satisfies the most demanding applications.

Tungsten carbide is used in machining tough materials such as cast iron or steel, as well as in situations where other tools would wear away, such as mining tools and wear parts. Most of the time, carbide will leave a better finish on the part,and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools.

| GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

We has a complete carbide production line,we are manufacturer, so we can control the goods quality from raw material, production process, strictly quality inspection after finishing, also we have import and export license, we can export to our customers directly, our foreign trade manager have above 10 years carbide experience, can understand customer’s requirement well and correctly.

All employees of our company adhere to the principle of "Producing with quality, developing with innovation and creating benefits through management". We make concerted efforts and innovate constantly to build mutual benefit business relationship with all of our distinguished customers.

Warmly welcome to contact us and visit us!