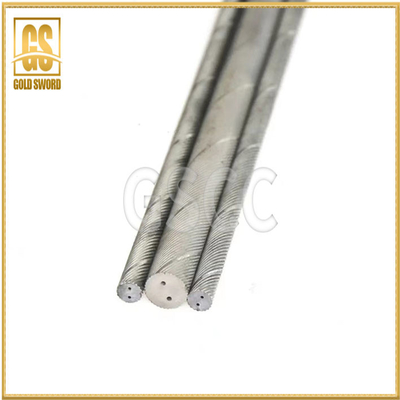

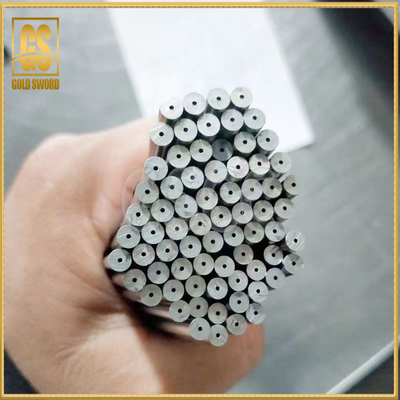

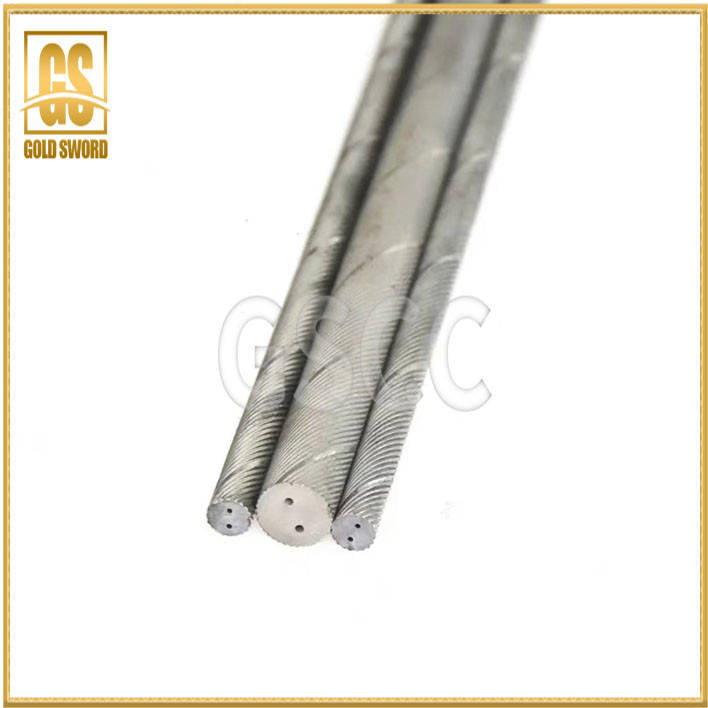

Conductors Polishing Tungsten Carbide Rods With 30 degree helical Hole

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Certification: | ISO9001 |

| Model Number: | can be customized, with hole |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Material: | Tungsten Carbide | Free Samples: | Available |

|---|---|---|---|

| Commodity Name: | Tungsten Carbide Products | Tolerance: | Polishing Or Tolerance Of H6 H6 H5 |

| Application: | Processing Lathe, Conductors, Steel-making Burdening And Additives | ||

| High Light: | ISO9001 Tungsten Carbide Rods,Conductors Tungsten Carbide Rods,Polishing Hole Tungsten Square Bar |

||

Product Description

Tungsten Carbide Rods With Hole Are Mainly Used For Processing Tungsten Parts Or As A Tool Bit Of Processing Lathe, Cond

Application of Cemented Carbide Rods Blank

1. For making carbide mold punches

2. For making carbide core pins

3. For making carbide dental burrs

4. For making carbide PCB drills, drills, end mills & hole drilling tools, boring bar

5. For making carbide reamers

Carbide round bars have superior hardness, flexural strength, concentricity and straightness.

The round bar is press molded by molding and extrusion.

The cemented carbide round bar is sintered by a vacuum integrated furnace or a high-pressure sintering furnace, and has high overall performance and no porosity.

The carbide rods are used for cutting aluminum alloy, cast iron, stainless steel, Refractory alloy steel, nickel-based alloy, titanium alloy and nonferrous materials, For making PCB drills, drills, end mills &reamers, mold punches ,core pins & hole drilling tools, etc.

The Features and the uses of cemented carbide

| Mark | ISO standard |

Density g/cm³ |

Hardness HRA |

Bending strength ≥ MPa |

Grain size | Features and notice | use |

| RX20 | K05 | 14.5 | 91.2 | 2100 | fine | Comprehensive properties, high hardness and high strength alloys widely used in woodworking field | Suitable for all types of wood processing, also for the processing of metal and non-metal materials |

| RX10T | K10 | 14.5 | 91.8 | 1800 | fine | The cutting edge is sharp and the wear resistance is very good. It is easy to crack at high temperatures. It is recommended to use high frequency induction welding or automatic welding machine. | It is suitable for the cutting of high-density boards, high-fiber boards and particleboards for woodworking tools. It is also suitable for finishing and semi-finishing of cast iron, non-ferrous metals and alloys. |

| RX10 | K10 | 14.75 | 90.5 | 2200 | medium | Good wear resistance and impact resistance, resistance welding can be used. | It is used for impact-resistant and nail-proof cutting of dry wood, cork, mixed wood and cement board, and is suitable for all types of forming knives in the furniture manufacturing industry. |

| YG6X | K10 | 14.9 | 90.8 | 1950 | fine | Good abrasion resistance | It is suitable for machining cold hard cast iron and heat resistant alloy, also suitable for finishing common cast iron. It is used to make casing cemented carbide tools and wear resistant parts. |

| YG6 | K20 | 14.95 | 90.5 | 2000 | medium | It has good wear resistance and impact toughness. Resistance welding can be used, but the welding temperature should not be too high. | It is suitable for the processing of ordinary cutting wood saws, cast iron aluminum profiles and copper rods. |

| YG8 | K20 | 14.80 | 89.5 | 2000 | medium | It has good wear resistance and impact toughness. Resistance welding can be used, but the welding temperature should not be too high. | It is suitable for the processing of non-ferrous metal profiles, dry wood, cork and hardware tools. Suitable for making ordinary sawtooth, it can also be used to make wear parts, general holes and metal processing. |

| YG8Ak | K20 | 14.75 | 90.0 | 2200 | medium | Wear resistance and hardness are good, resistance welding can be used, but welding temperature should not be too high. | Suitable for the processing of hardwood and ordinary wood |

| YG8C | K30 | 14.75 | 88.5 | 2300 | thick | Good impact toughness | Suitable for artificial marble, common wood with weeds, weeds and thickets. |