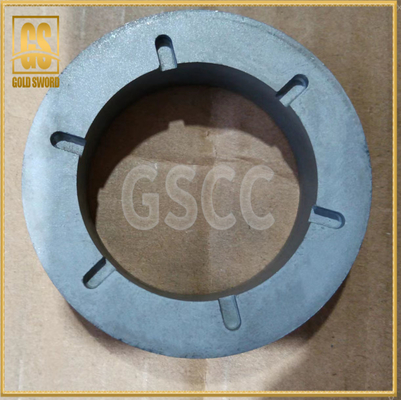

Tungsten Carbide Petroleum Machinery Parts Bearing Bushing Group Pad Impact Resistance

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Certification: | ISO9001 |

| Model Number: | 7LZ73CJ*7.0-07/7LZ73CJ*7.0-07 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Material: | Carbide,Tungsten Carbide WC+Co, Tungsten Cobalt Alloy. | Service: | OEM / ODM |

|---|---|---|---|

| ISO Code: | K05 / K20 / K30 /K40 | Application: | Wear Parts |

| Usage: | Petroleum Machinery Parts | ||

| High Light: | Tungsten Carbide Bearing Bushing Group Pad,Petroleum Machinery Bearing Bushing Group Pad,Petroleum Machinery Tungsten Bearing Bushing |

||

Product Description

Tungsten Carbide Petroleum Machinery Parts Bearing Bushing Group Pad Impact Resistance

The tungsten carbide ground finish cold heading dies are used for cold punching and heading of srew and nuts, it is wear resistance and high toughness. Also, it is the ideal in making non-ferrous metal, ferrous metal and other alloy.

Description of Tungsten Carbide Bearings

1. The purity of raw materials is more than 99.95%, the impurities are less, and the physical properties of the board are more stable;

2. Using spray drying technology, the material is protected by high-purity nitrogen under fully airtight conditions, which effectively reduces the possibility of mixing oxygen during the preparation process, the purity is better, and the material is not easy to be dirty;

3. The carbide density is uniform: 300Mpa isostatic pressing can effectively prevent the occurrence of defects, and the density of the plate is more uniform;

Tungsten carbide is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through a process called sintering for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments, and jewelry.

| Grade | Density (g/cm3) | Hardness (HRA) | TRS (N/mm2) | ISO Code | Applications |

| JGR05 | 15.15 | 94 | 2000 | K05 | With excellent wear resistance,suitable for making nozzles,small sized drawing dies and micropore drawing dies |

| K10UF | 14.9 | 93 | 2600 | K05 | |

| K10S | 14.9 | 91 | 2450 | K20 | With excellent wear resistance,suitable for making nozzles,small sized drawing dies and woodworking carbide strips |

| YG6 | 14.9 | 91 | 2450 | K20 | Medium grain,with good wear resistance and toughness,suitable for making medium and small sized drawing ies and woodworking carbide strips |

| YG8 | 14.7 | 90 | 2000 | K20 | Medium grain,with extensively applicable wear resistance and toughness,suitable for making various-sized drawing dies material and woodworking carbide strips |

| JG08 | 14.65 | 90 | 3000 | K20 | Medium grain,with high toughness,suitable for making various top grade die material and woodworking strips |

| YG11 | 14.45 | 88.5 | 2600 | K30 | Medium grain,with good impact resistance and toughness,suitable for making medium and large sized drawing dies |

| YG15 | 14.1 | 87 | 2600 | K40 | Suitable for making steel pies and steel rods under strong stress and big compressibility,also can be making punching dies under large impact load |

| JG15A | 14 | 87.5 | 3000 | K40 | With high toughness and excellent impact resistance,suitable for making vaious top grade step processing dies |

| YG20 | 13.6 | 85 | 2600 | K50 | Suitable for making punch dies,such as bolts and nuts |

| JG20 | 13.65 | 85 | 3200 | K50 | Suitable for making punch dies,such as bolts and nuts |

| YG20C | 13.6 | 83 | 2600 | K50 | Suitable for making punch dies such as watch components,musical instrument reeds,small sized steel bals,normal impact resistance forging dies |

![]()

![]()

![]()

![]()

![]()

FAQ

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the samples,but not free of charge.

Q: How to get a quotation and order?

A: Just send your CAD/PDF drawing and demand.

Q: What's the price?

A: According to customer's requirements and quantity.The prices is depending on the material and the tolerance demand.