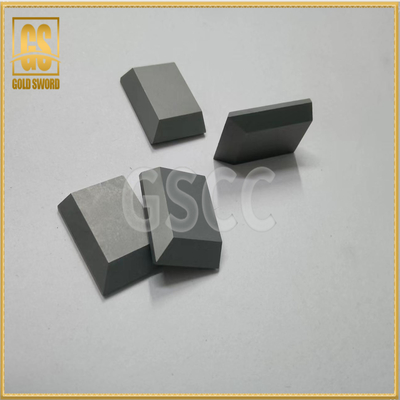

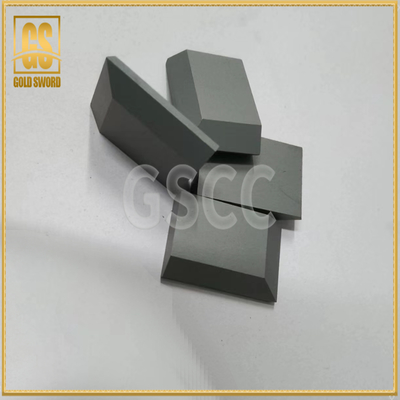

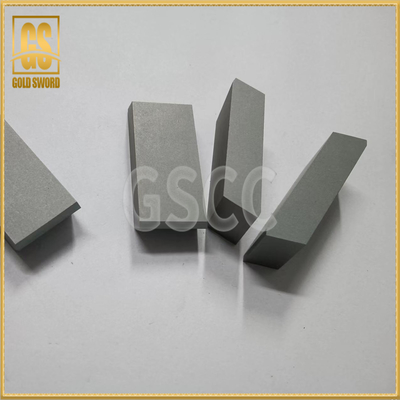

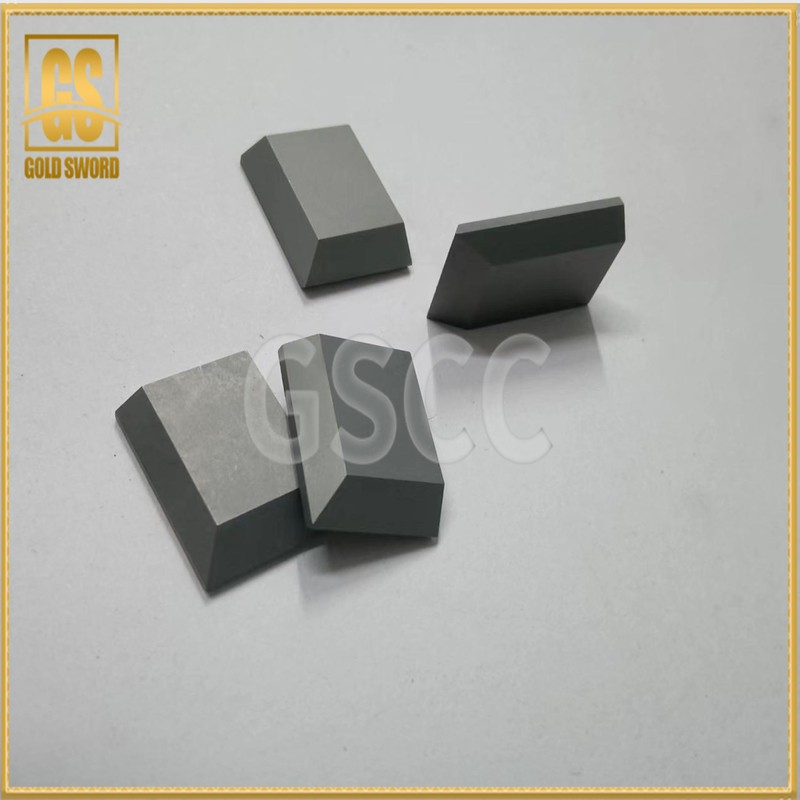

Blank Tungsten Carbide Alloy Products YG10X Impact Toughness For Hardware Tools

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Certification: | ISO9001 |

| Model Number: | customized, 4*8*10-35 degree |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Features: | Excellent Wear Resistant And High Hardness,long Lasting Use,sharp Point | Item: | Cemented Carbide |

|---|---|---|---|

| Color: | Gray | Surface: | Polished |

| Grade: | YG8C/YG10X/YG12 | Usage: | Stone Carving, Hardware Tools |

| Customized: | Accepted | Package: | Safety Exporting Packing,Plastic Tube Or Plastic Box |

| High Light: | Blank Tungsten Carbide Alloy YG10X,HRA90 Tungsten Carbide Alloy,14.5g/cm3 Custom Tungsten Carbide |

||

Product Description

About the carbide cemented

Cemented carbide is a hard material used extensively as cutting tool material, as well as other industrial applications. It consists of fine particles of carbide cemented into a composite by a binder metal. Cemented carbides commonly use tungsten carbide (WC), titanium carbide (TiC), or tantalum carbide (TaC) as the aggregate. Mentions of "carbide" or "tungsten carbide" in industrial contexts usually refer to these cemented composites.

The Features and the uses of cemented carbide

| Mark | ISO standard |

Density g/cm³ |

Hardness HRA |

Bending strength ≥ MPa |

Grain size | Features and notice | use |

| RX20 | K05 | 14.5 | 91.2 | 2100 | fine | Comprehensive properties, high hardness and high strength alloys widely used in woodworking field | Suitable for all types of wood processing, also for the processing of metal and non-metal materials |

| RX10T | K10 | 14.5 | 91.8 | 1800 | fine | The cutting edge is sharp and the wear resistance is very good. It is easy to crack at high temperatures. It is recommended to use high frequency induction welding or automatic welding machine. | It is suitable for the cutting of high-density boards, high-fiber boards and particleboards for woodworking tools. It is also suitable for finishing and semi-finishing of cast iron, non-ferrous metals and alloys. |

| RX10 | K10 | 14.75 | 90.5 | 2200 | medium | Good wear resistance and impact resistance, resistance welding can be used. | It is used for impact-resistant and nail-proof cutting of dry wood, cork, mixed wood and cement board, and is suitable for all types of forming knives in the furniture manufacturing industry. |

| YG6X | K10 | 14.9 | 90.8 | 1950 | fine | Good abrasion resistance | It is suitable for machining cold hard cast iron and heat resistant alloy, also suitable for finishing common cast iron. It is used to make casing cemented carbide tools and wear resistant parts. |

| YG6 | K20 | 14.95 | 90.5 | 2000 | medium | It has good wear resistance and impact toughness. Resistance welding can be used, but the welding temperature should not be too high. | It is suitable for the processing of ordinary cutting wood saws, cast iron aluminum profiles and copper rods. |

| YG8 | K20 | 14.80 | 89.5 | 2000 | medium | It has good wear resistance and impact toughness. Resistance welding can be used, but the welding temperature should not be too high. | It is suitable for the processing of non-ferrous metal profiles, dry wood, cork and hardware tools. Suitable for making ordinary sawtooth, it can also be used to make wear parts, general holes and metal processing. |

| YG8Ak | K20 | 14.75 | 90.0 | 2200 | medium | Wear resistance and hardness are good, resistance welding can be used, but welding temperature should not be too high. | Suitable for the processing of hardwood and ordinary wood |

| YG8C | K30 | 14.75 | 88.5 | 2300 | thick | Good impact toughness | Suitable for artificial marble, common wood with weeds, weeds and thickets. |

Products profile

![]()

![]()

2. With the support of advanced molding technology and production finishing equipment, the dimensional accuracy of the product is very high.

3. Dust-free workshop to ensure product quality, uniform density and no pinholes.

4. All products have passed the quality inspection and can stand the test. The company's defense: the quality is manufactured, not tested!

5. Efficient and professional service team to reduce your operating costs.

6. Special materials and complex shapes are our company's pursuit of excellence.

7. We accept non-standard shaped parts to pull small batch sample test orders. We are not afraid to try, but we are afraid that the product will not be recognized.