KG7 WF40 GU10F YG15 9 Thread Holes 400mm Polishing Fine Sharpening Blade For Plastic Pelletizer

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | pcs |

| Packaging Details: | In one carton or as your wish, plastic box, Neutral packing or per customers' request |

| Delivery Time: | 15-30 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000pcs/month |

|

Detail Information |

|||

| Size:: | Cusotmized,angel, 10*30*358/404/524 | Application:: | Cutting And Processing |

|---|---|---|---|

| Material:: | Tungsten Carbide | Commodity Name:: | Cemented Carbide Products |

| Keywords: | Tungsten Carbide Strips In VSI Stone Crusher, Plastic Cutters Tips,Aluminum Cutters,countersink Tungsten Strips | Hole Spacing: | 55mm/45mm |

| Hole Type: | Threaded Hole / Tapered Hole/through-hole | ||

| High Light: | 400mm Polishing Fine Sharpening Blade,9 Thread Holes Sharpening Blade,Plastic Pelletizer Fine Sharpening Blade |

||

Product Description

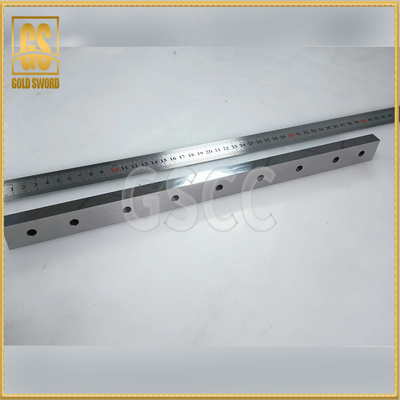

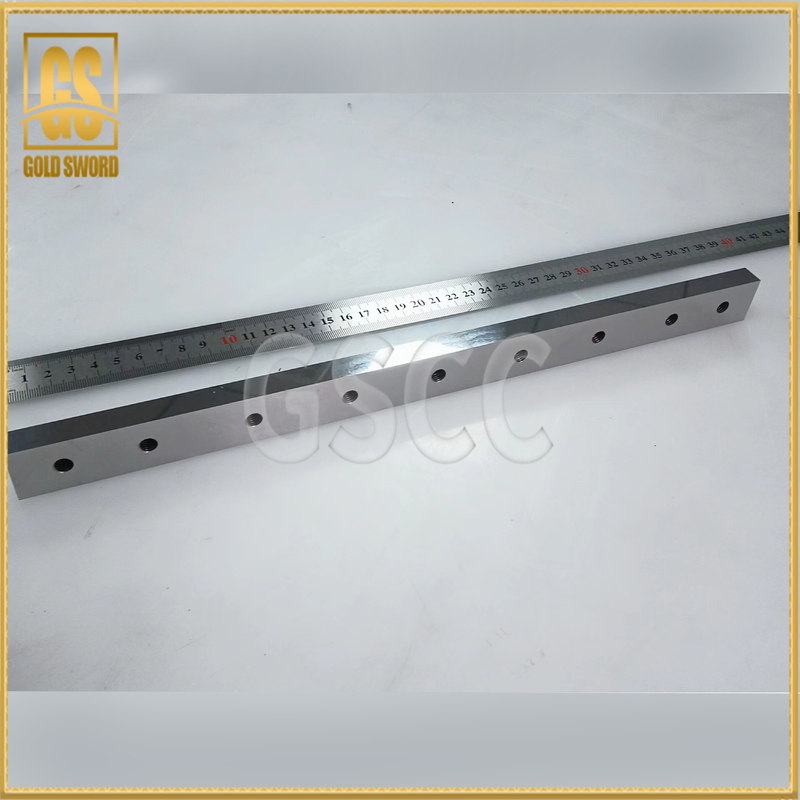

KG7/ WF40/GU10F / YG15 9 Thread Holes 400mm Long Polishing Fine Sharpening Blade For Plastic Pelletizer

The cemented carbide is formed by powder metallurgy, heated under vacuum, and undergoes the vacuum dewaxing sintering process, which is beneficial to remove impurities, improve the purity of the sintering atmosphere, improve the wettability of the binder phase, promote the reaction, and finally form a compact with a certain chemical The composition and physical and mechanical properties of the structure of cemented carbide.

Tungsten carbide precision tools, on the basis of blank opening, grinding, line cutting, fine grinding, pollishing,installed on the machine tools, durable performane than high speed steel, longer life, better flatness, corrosion erosion resistance.

Main material and Applications

| Tungsten carbide strips Product Properties | |||

| Grade: | YG15/KG7 | Brand: | GoldSword |

| Measure: | 3/4/5*10*1670/2000/2300 | Place of origin: | ZhuZhou |

| WC+Others: | 85% | Co content: | 15% |

| Grain: | 1.2~2.0 | Density: | 14g/cm3 |

| Hardness: | 87-88HRA | T.R.S: | 3800-4000 N/mm2 |

workshop production flow

![]()

![]()

![]()

products photogragh

![]()

![]()

![]()

![]()

Carbide strips are mainly used for hardware tools, mechanical assembly knives and cutting blades. It can also be used for cutting and punching. Used in papermaking, packaging, printing, non-ferrous metal processing and other industries. In addition, it is also widely used for machining high-speed steel tools, carbide milling cutters, carbide tools, cutting tools, aviation tools, carbide drills.

Features: high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance.

The production process of cemented carbide strip, first of all, the production and forming process of the strip, what kind of mold and raw materials are used, according to the shrinkage coefficient and the required product specifications, design the pressing thickness, pressing unit weight, pressure, holding time, etc. .

In the actual manufacturing process, after the operator receives the process sheet, the operator first takes the material, checks the equipment, weighs the unit weight, then fills and scrapes the material, then presses and forms under the pressure of the pressure cylinder, and then demolds, and the pre-formed product Out.

After the blank comes out, the rough grinding line cutting after fine grinding, cutting edge, punching, etc., and then polishing, it can be directly installed on the machine to work.

Tools display

![]()

Contact manager

Wechat/Phone:15873380794

Tel/Fax:0731-28254758

E-mail:tracy@goldswordcarbide.com

QQ:156044898

Web:www.goldswordcarbide.com