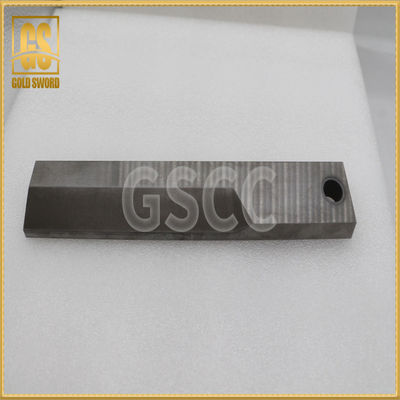

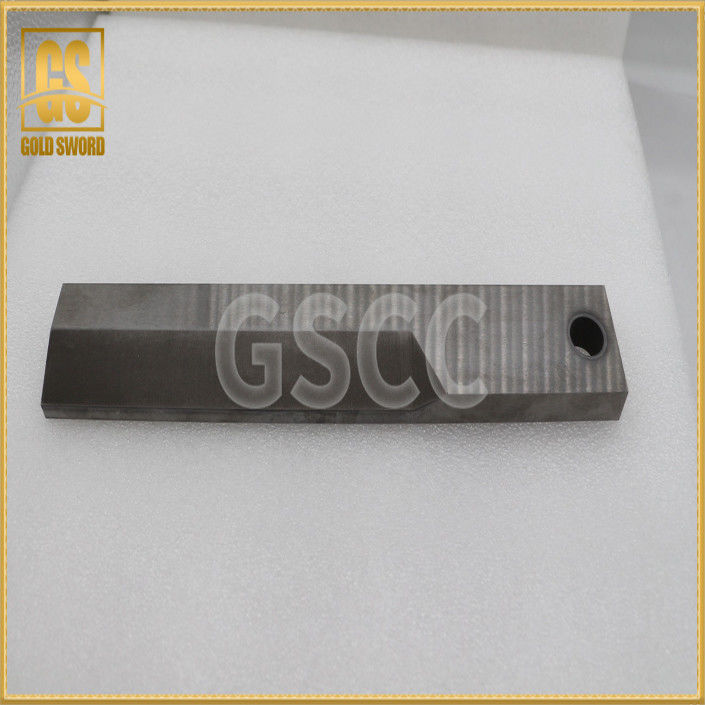

High Toughness Tungsten Carbide Flat Bar Model Number Customized Size Various

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | kilogramme/pcs |

| Packaging Details: | boxes, carton |

| Delivery Time: | 15-30 days |

| Payment Terms: | FOB, L/C, T/T |

| Supply Ability: | 30000pcs/month |

|

Detail Information |

|||

| Material: | 100% Virgin Tungsten Carbide,WC+CO Good Raw Material | Grade: | YG6X/YG6/YG8/YG15/YG20 Etc.,We Can Recommend Based On Your Application |

|---|---|---|---|

| Product Name: | Flat Bars Sheets Tungsten Carbide Strips,Hot Selling Tungsten Cemented Carbide Flat Bars Alloy Strips | Surface: | Polished,Blanks Or Polished Grinding,Blank(Unground),Sandblasting |

| Size: | Customer's Request,OEM Accepted,Customizable,up To Your Requirement | Advantage: | High Wear Resistance,More Than 20 Years Experience,Smooth And Straight Cut,Excellent Wear Resistance And Hardness |

| Name: | Cemented Carbide Square Yg8 Flat Bar/strips K10&k20 Carbide Bar/strips,Cemented Carbide Strips,Tungsen Carbide Strips | ||

| High Light: | High Toughness Tungsten Carbide Flat Bar,YG6X Tungsten Carbide Flat Bar,Sandblasting Tungsten Carbide Strips |

||

Product Description

High Toughness Tungsten Carbide Flat Bar Model Number Customized Size Various

Applications:

1. Carbide Square Bar is made from tungsten carbide powders and cobalt powders .With its wear resistant and corrosion resistant ability , tungsten carbide nowadays is widely used in many areas such as : cutting tools , moulds , oil and automobile industry etc .

2. Carbide Square Bar is used as the cutter for the TCT woodworking knives used for cutting all kinds of original wood , hard wood , HDF, MDF , plywood , particle board , laminated board, composite material ,grass, aluminum and metals . It can give much more excellent performance than HSS .

1. Easy brazing

2. High wear-resistance and high-toughness

3. 100% use virgin raw materials, our constant is quality in every order we produce, large or small

4. OEM and ODM service, professional R and D department is ready to design products to fit your specifications, they can offer the professional advice and CAD drawing for you

5. Sample available

Applications:

Tungsten carbide strips widely known as one kind of carbide cutting tools, it's available for different grinding geometric parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional, carbide inserts semi-automatic lathe, automatic lathe and planning machine to work grooves and operate cutting

|

GSGrade |

ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | It has high hardness, good toughness and good overall performance. It is suitable for processing all kinds of solid wood, mahogany, medium density board, non-ferrous metal, gray cast iron, etc. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

| YN15 | K40 | 14-14.2 | 85-86 | 1700-1900 | Medium |

Mainly used for stamping moulds and ceramic die of electronic components, petroleum machinery corrosion resistant instrument, without magnetic.

|

| SK40S | K10 | 14.5 | 91 | 3000-3200 | Fine | High On the basis of ensuring high bending strength, the wear resistance of the alloy is improved, the cutting edge is dense and sharp, which is conducive to the flatness of processing, and has good welding performance. It is used for food package, printing, aluminum foil, metalized film, and gardens. , Textile, leather, plastic, rubber and other mechanical blades. |

Advantages:

1. We are a professional tungsten carbide manufacturer in Zhuzhou city over 20-year and have a few senior engineers who specialize in tungsten carbide field for many decades

2. Recommended grade: YG6 (K10), YG6X YG8 (K20), YG15 (K30), we can research and develop more suitable formula according to use condition and processing characteristics for client

3. For your non-standard parts, we have strong ability to make mold by ourselves and produce them per your requirements

4. We have strict quality control and assurance system to guarantee the consistent quality

![]()

![]()

![]()

![]()