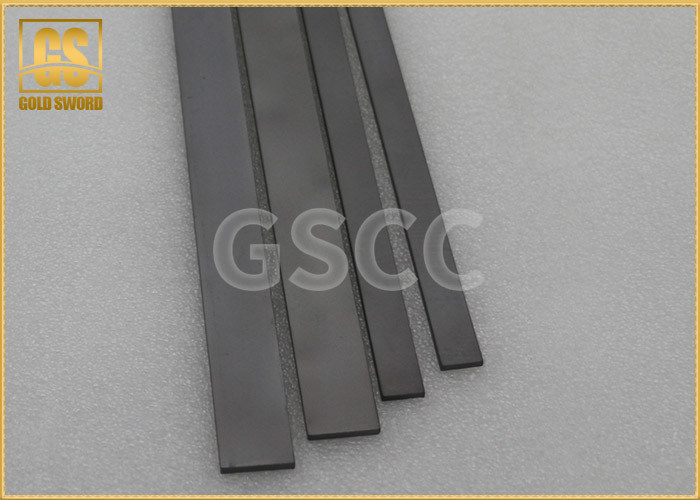

Solid Wood Cutting Tungsten Carbide Blanks High Temperature Resistance

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Model Number: | rectangular carbide blanks |

Payment & Shipping Terms:

| Minimum Order Quantity: | negotiate |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

| Supply Ability: | 80000 pcs per month |

|

Detail Information |

|||

| Type: | Rectangular Carbide Blanks | Performance: | High Toughness |

|---|---|---|---|

| Color: | Grey | Feature: | Solid Wood Cutting |

| Highlight: | solid carbide blanks,carbide insert blanks |

||

Product Description

Solid Wood Cutting Tungsten Carbide Blanks High Temperature Resistance

Tungsten carbide rod shows all the superiorities of tungsten carbide, such as good wear and corrosion resistance, high toughness, etc.

Precisely speaking, its chemical composition is mainly tungsten carbide powder, with Co or Ne as its binder.

Tungsten carbide rods with several TC Grades used for various metals and non-metal cutting tools for such as drills, end mills, reamers.

Also widely used in stamping tools and wear-resistant tools,etc.

Feature:

Tungsten carbide strip is mainly composed of tungsten carbide and cobalt powder mixed by metallurgical methods, including powder making, ball grinding, pressing and sintering. The main alloy components are WC and Co. The contents of WC and Co in tungsten carbide strip with different uses are not consistent, and the application range is wide. Cemented carbide strip is characterized by high red hardness, good weldability, high hardness and high wear resistance. It is mainly used in the manufacturing of solid wood, density board, grey cast iron, non-ferrous materials, cold hard cast iron, hardened steel, PCB and brake materials.

| THICKNESS | WIDTH | LENGTH | |||

| Size | Tolerance | Size | Tolerance | Size | Tolerance |

| 1~3 | 0~+0.3 | 4~6 | 0~+0.2 | 5~30 | 0~+0.5 |

| 3~5 | 0~+0.4 | 6~10 | 0~+0.3 | 30~60 | 0~+1 |

| 5~8 | 0~+0.5 | 10~15 | 0~+0.4 | 60~100 | 0~+1.5 |

| 8~12 | 0~+0.8 | 15~20 | 0~+0.5 | 100-150 | 0~+2 |

| 12~15 | 0~+1 | 20~25 | 0~+0.8 | 150~200 | 0~+2.5 |

| >15 | 0~+1.2 | 25~30 | 0~+1 | 200~250 | 0~+3 |

| 30~40 | 0~+1.5 | 250~300 | 0~+4 | ||

| 40~50 | 0~+2 | 300~350 | 0~+5 | ||

| 50~80 | 0~+3 | 350~450 | 0~+8 | ||

| >80 | 0~+5 | >450 | 0~+10 | ||

| 1,The deformation amount of the plane of ordinary specifications is no more than 0.3mm, and that of the side is no more than 0.5mm | |||||

| 2,Thickness <2MM, width BBB 0 20MM, lateral deformation less than or equal to 1MM | |||||

When requesting for a quote specify:

1. Physical dimensions, and related tolerance ( if you have)

2. Grade, or chemical composition (WC: Wt% + Co: Wt% + Others : Wt%) , and properties (Hardness, Density, coercive force, and WC grain size), and associated tolerances, etc.

3. Operation condition and special requirement.

4. Surface condition: sintered blank, fine grinding.

5. Quantity needed.

Only in this way, we can judge and quote exactly on time.