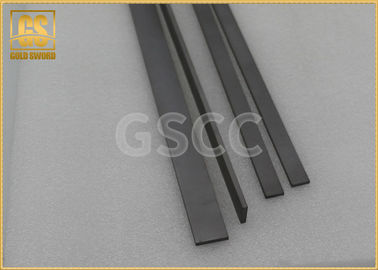

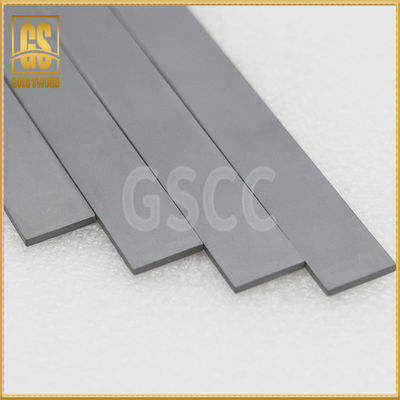

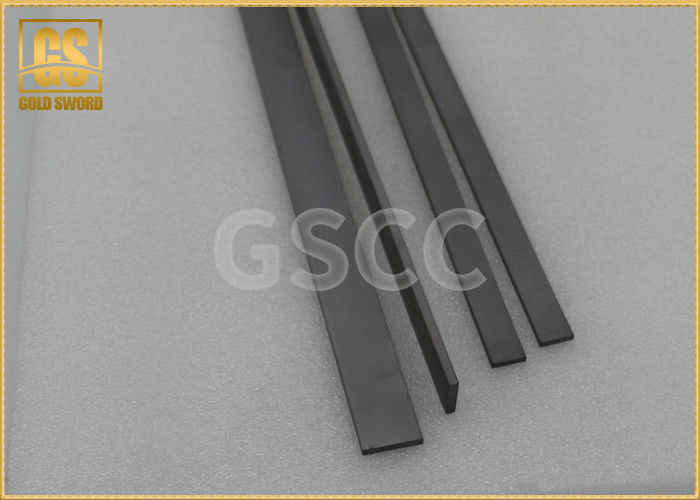

Temperature Resistant Tungsten Carbide Blanks With Longer Service Life

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Model Number: | Tungsten Carbide Blanks |

Payment & Shipping Terms:

| Minimum Order Quantity: | negotiate |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Name: | Tungsten Carbide Blanks | Performance: | Temperature Resistant |

|---|---|---|---|

| Color: | Grey | Advantage: | Longer Service Life |

| Highlight: | carbide tool blanks,solid carbide blanks |

||

Product Description

Temperature Resistant Tungsten Carbide Blanks With Longer Service Life

Introduction of Tungsten Carbide Blanks

Compared with steel strips, tungsten carbide strips are much more wear resistant and temperature resistant. They're widely use in many field such as woodworking, machining of refractory alloys, stainless steel, high manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar, etc.

Advantages of Tungsten Carbide Blanks:

1. made from 100% virgin raw material;

2. produced with advance equipments and process;

3. all products go through in-process and final inspection

| THICKNESS | WIDTH | LENGTH | |||

| Size | Tolerance | Size | Tolerance | Size | Tolerance |

| 1~3 | 0~+0.3 | 4~6 | 0~+0.2 | 5~30 | 0~+0.5 |

| 3~5 | 0~+0.4 | 6~10 | 0~+0.3 | 30~60 | 0~+1 |

| 5~8 | 0~+0.5 | 10~15 | 0~+0.4 | 60~100 | 0~+1.5 |

| 8~12 | 0~+0.8 | 15~20 | 0~+0.5 | 100-150 | 0~+2 |

| 12~15 | 0~+1 | 20~25 | 0~+0.8 | 150~200 | 0~+2.5 |

| >15 | 0~+1.2 | 25~30 | 0~+1 | 200~250 | 0~+3 |

| 30~40 | 0~+1.5 | 250~300 | 0~+4 | ||

| 40~50 | 0~+2 | 300~350 | 0~+5 | ||

| 50~80 | 0~+3 | 350~450 | 0~+8 | ||

| >80 | 0~+5 | >450 | 0~+10 | ||

| 1,The deformation amount of the plane of ordinary specifications is no more than 0.3mm, and that of the side is no more than 0.5mm | |||||

| 2,Thickness <2MM, width BBB 0 20MM, lateral deformation less than or equal to 1MM | |||||

Tungsten Carbide Blanks Benefits

* Substantially longer service life than traditional steel tools

* Consistent working depth and tillage quality

* Permanently sharp cutting edges mean improved heeling and less traction power required

* Needs no depth adjustment due to wear

* Saves time and money thanks to fewer blade changes

* Much longer periods of use during good weather

* Optimum utilization of machine power

* Lower tool costs per acre

* Money saved through reduced stocks

![]()

![]()

woodworking knife

![]()

![]()

![]()