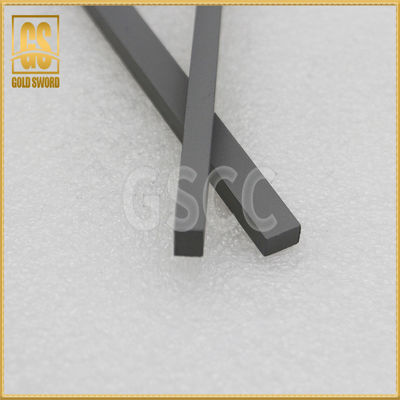

HRA89 Standard Finish Grind Tungsten Carbide Strips

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | 5*15*200,10*20*320,STB |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | pcs |

| Packaging Details: | boxes, carton |

| Delivery Time: | 15-30 days |

| Payment Terms: | FOB, L/C, T/T |

| Supply Ability: | 20000pcs/month |

|

Detail Information |

|||

| Material: | 100% Virgin Tungsten Carbide,Tungsten Carbide WC+Co,WC+CO Good Raw Material | Application: | Processing Original Wood,End Mill.cutting Tools |

|---|---|---|---|

| Grade: | K30,K20,YG6X/YG6/YG8/YG15/YG20 Etc. | Product Name: | Hard Metal Strip,flat Bars Sheets Tungsten Carbide Strips,Hot Selling Tungsten Cemented Carbide Flat Bars Alloy Strips |

| Surface: | Polished,Blanks Or Polished Grinding,Sandblasting | Hardness: | HRA89-HRA92.9 |

| Chemical Composition: | WC+CO | Shape: | Tungsten Carbide Strip,Customized |

| High Light: | Grind Tungsten Carbide Strips,Standard Tungsten Carbide Strips,HRA89 Tungsten Carbide Strips |

||

Product Description

Standard Finish Grind Tungsten Carbide Strips

Tungsten carbide strips have high hardness, wear-resistance, and resistance to bending. They're widely used in cutting tool, crusher, wear parts, moulding base and other fields. We provide various size, such 5*5*320mm,3*3*320mm, 4*4*300mm, 6*6*300mm, all STB sizes and your customized sizes are welcomed.

Tungsten carbide strip description

1, the purity of more than 99.95% of raw materials, impurities, less physical properties of the plate more stable;

2, the use of spray drying technology, the material in the fully sealed conditions using high purity nitrogen protection, effectively reduce the mixing process in the preparation of the possibility of oxygen, better purity, the material is not easy to dirty;

3, the density of tungsten carbide strip uniform: 300Mpa isostatic pressing machine to suppress, effectively prevent the production of defects, the strip density is more uniform;

Tungsten carbide strip Characteristics

1, Tungsten carbide strip with fine compactness, strength and hardness indicators are in line with the standard: the use of low-pressure sintering technology, so that the pores within the strip to be effectively eliminated, the quality is more stable.

2, the use of cryogenic treatment technology, so that the internal microstructure of the strip to be improved, the internal stress can be greatly reduced, effectively avoid the strip in the cutting process of the possibility of cracks generated;

Tungsten carbide strip application

1, suitable for the production of cast iron roll and high nickel chrome roll dressing knife;

2, for the production of discharge strip, stamping die, punch, electronic progressive die and other stamping die, etc.

Tungsten Carbide strip is used for cutting general wood cutters, hard wood cutters, plastic and tobacco, as well as to making drawing dies, wear parts and module core for punching parts and automatic press and etc.

Tungsten carbide strip dimensions and grade

|

GSGrade |

ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | It has high hardness, good toughness and good overall performance. It is suitable for processing all kinds of solid wood, mahogany, medium density board, non-ferrous metal, gray cast iron, etc. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

| YN15 | K40 | 14-14.2 | 85-86 | 1700-1900 | Medium |

Mainly used for stamping moulds and ceramic die of electronic components, petroleum machinery corrosion resistant instrument, without magnetic.

|

| SK40S | K10 | 14.5 | 91 | 3000-3200 | Fine | High On the basis of ensuring high bending strength, the wear resistance of the alloy is improved, the cutting edge is dense and sharp, which is conducive to the flatness of processing, and has good welding performance. It is used for food package, printing, aluminum foil, metalized film, and gardens. , Textile, leather, plastic, rubber and other mechanical blades. |