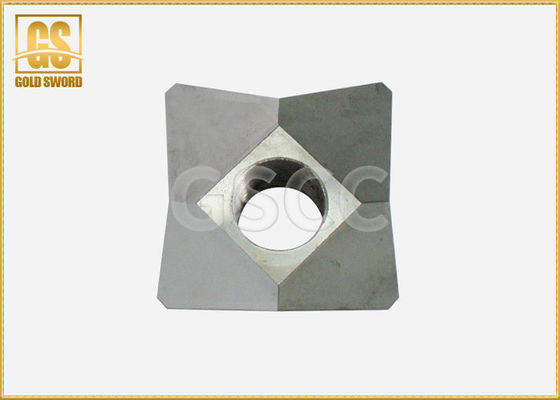

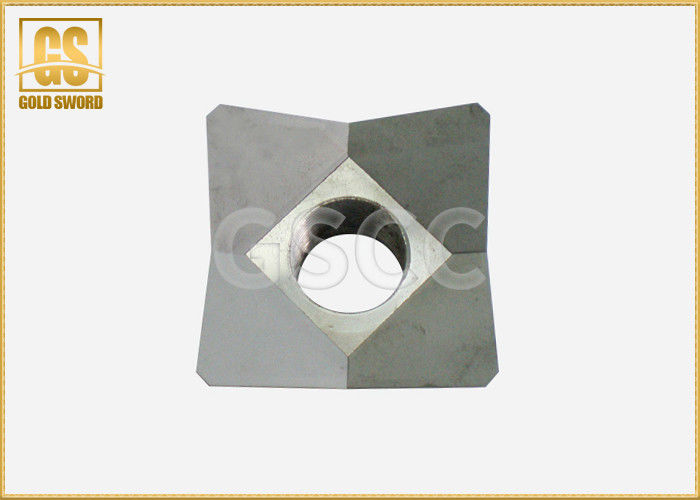

ISO9001 Approved Custom Tungsten Carbide Blade High Precision

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | pcs |

| Packaging Details: | paper boxes, wooden boxes、carton,Iron barrel |

| Delivery Time: | 15-30 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000pcs/month |

|

Detail Information |

|||

| Features: | Excellent Wear Resistant And High Hardness,long Lasting Use,sharp Point | Surface: | Blanks Ungrounded/ground/grinded/polished Or As Requirment,coated (as Required) |

|---|---|---|---|

| Shape: | Customized,Various Shapes | Advantage: | Durable,factory,30 Years Experience,Customer-customized Finishing Blades Can Quickly Formulate Product Plans Based On Customer Processing Conditions And Requirements, With Fast Quotation, High Precision, And Fast Processing. |

| Packing: | Brown Paper Box,customized,Plastic Box+Wood Carto | ||

| High Light: | Custom Tungsten Carbide Blade,ISO9001 Custom Tungsten Carbide,Tungsten Carbide Blade High Precision |

||

Product Description

Customer-customized finishing blades can quickly formulate product plans with fast quotation, high precision, and fast p

![]()

1.Strong R&D team. Professional engineers serve for clients, recommend products and grades as per your applications. We also offer after-sale service.

2.Strong Mould R&D team. We support product customization as per specific requirements, ensure high working efficiency with good product quality.

3.Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

4. Customer-customized finishing blades can quickly formulate product plans based on customer processing conditions and requirements, with fast quotation, high precision, and fast processing.

![]()

![]()

Product Description

Virgin Tungsten Carbide Die Moulds

virgin Tungsten Carbide Die moulds for drawing brass&steel material YG6/YG8

![]()

| GRADE | ISO | DENSITY | HARDNESS | TRS | Applications recommended |

| GRADE | (g/cm3) | (HRA) | (N/mm2) | ||

| YG3 | K05 | 15.1 | 92 | 1400 | Suitable for finishing of cast iron and nonferrous metal. |

| YG6X | K10 | 14.95 | 91.5 | 1800 | The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

| YG6 | K15 | 14.95 | 90.5 | 1900 | Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG8 | K20 | 14.8 | 89.5 | 2200 | |

| YW1 | M10 | 13.1 | 91.6 | 1600 | Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

| W2 | M20 | 13 | 90.6 | 1800 | The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

| YT15 | P10 | 11.4 | 91.5 | 1600 | Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

| YT14 | P20 | 11.6 | 90.8 | 1700 | Suitable for the finishing and semi-finishing of steel and cast steel. |

| YT5 | P30 | 12.9 | 90.5 | 2200 | Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

![]()

![]()

![]()

![]()

![]()

![]()

![]()