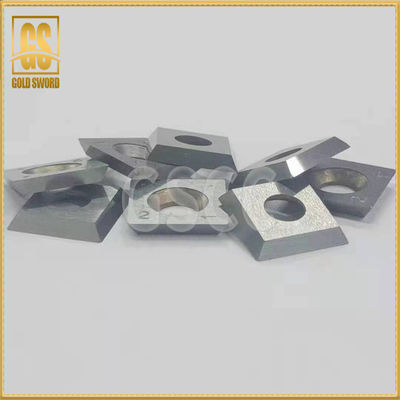

Disposable blades for woodworking spiral cutters Four-side planer alloy blades for end mills

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | 14*14*2-35°,15*15*2.5-37°,30*12*1.5-30° |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10pcs |

|---|---|

| Price: | pcs |

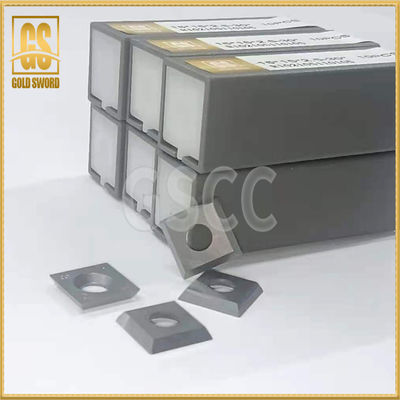

| Packaging Details: | In one carton or as your wish, plastic box, Neutral packing or per customers' request |

| Delivery Time: | 7-10 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20000pcs/month |

|

Detail Information |

|||

| Material: | 100% Virgin Tungsten Carbide Material,Hard Alloy | Usage: | Woodworking Cutting,indexable Blade,spiral Planers,Discarded Blade |

|---|---|---|---|

| Hardness: | 91.0-93.5HRC | Application: | Woodworking Cutting,indexable Blade,spiral Planer Inserts,Discarded Blade |

| Product Name: | Woodworking Cutting,indexable Blade,spiral Planer Inserts,Discarded Blade | Package: | Plastic Box,10pcs/ Box,in One Carton Or As Your Wish, |

Product Description

Discarded spiral planer inserts, indexable, precision cutter blade for spiral flat knife, good consistency, smooth processing, high efficiency, mature blade for woodworking tools.

![]()

1,Machined by high precision CNC peripheral grinding, good consistency, tolerance can reach μm.

2.Adequate inventory, each model is complete, the quantity is not much can be shipped at any time.

3.Years of woodworking tool service experience, understand woodworking process and production process, to be processed wood materials corresponding to the blade material has a good experience.

![]()

![]()

![]()

![]()

![]()

Disposable woodworking blade is a woodworking spiral planer with high accuracy and high blade consistency. There are two types of light cutting and heavy cutting. It gradually replaces the previous woodworking flat knife with higher processing accuracy and faster efficiency. The wood has better flatness. The current market promotion is very fast. It can be reused just by changing the blade, and the standard blade is more conducive to mass production. Our company specializes in the production of this standard blade, professionally serving the woodworking blade industry for more than 20 years, and has a good understanding of the performance and use of the product. The blade has stable performance and excellent appearance accuracy, which has been recognized by the market.

There are two types of light cutting and heavy cutting. It gradually replaces the previous woodworking flat knife.It is higher processing accuracy and faster efficiency.

1.Disposable inserts are precisely machined from specific blanks

2.Primary ultrafine particles

3.Spray granulation

4.TPA compression molding

5.Solid pressure sintering

6.Peripheral mold finishing, precision is controlled within one wire, and the consistency is good.

![]()

![]()