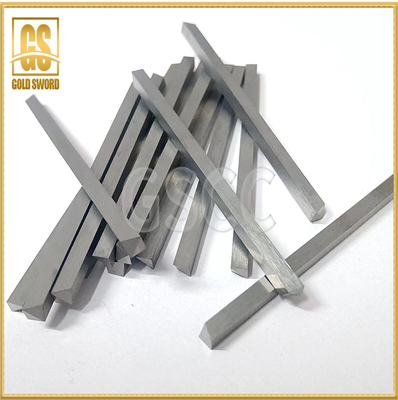

Carbide Tungsten Special Shaped Fine Grinding Chamfered Corners

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | pcs |

| Packaging Details: | In one carton or as your wish, plastic box, Neutral packing or per customers' request |

| Delivery Time: | 15~20 days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, T/T, Western Union |

| Supply Ability: | 30000pcs/month |

|

Detail Information |

|||

| Material: | Tungsten Carbide,100% Virgin Tungsten Carbide Material | Finished Product Processing: | Fine Grinding,Polished,wiring Cutting. |

|---|---|---|---|

| Finishing Equipment: | Walking Wire, Wire Cutting,grinding Machine,EDM,Lathe,Milling | Packing: | In One Carton Or As Your Wish,plastic Box,Neutral Packing Or Per Customers' Request |

| Product Name: | Tungsten Steel Sharpener Blade, Machine Repair Blade | ||

| High Light: | Carbide Tungsten Fine Grinding Chamfered Corners,Fine Grinding Tungsten Carbide Inserts,Special Shaped Fine Grinding Carbide Tungsten |

||

Product Description

Carbide Tungsten Special-Shaped Fine Grinding Shaped Chamfered Corners,

The use of cemented carbide strips

Application fields of carbide strips

Carbide strips processed into knives are widely used in ceramics, printing machinery, forestry, rubber, plastics, light textile industry, cigarette machinery, packaging materials, cables, shipbuilding, metallurgical machinery, electronics, leather and other industries, such as circular hard alloys. Alloy blade, asbestos gas cutting machine plastic granulator roll blade, round blade, slitting blade, sheet metal processing blade and other standard and non-standard mechanical blades.

Carbide strips are mainly used for cutting metal, wood, paper and other fields, therefore, their high quality is required to obtain longer life cycle and cutting speed.

Carbide bars are suitable for machining chilled cast iron and alloy steel. It can also be used in the production of precision machining, precision cast iron and wear parts.

Carbide strips have good flexural strength and wear resistance, not only for slow rough turning, heat-resistant Alois milling and semi-finishing of titanium, stainless, low-alloy steels, but also for machining Production of glass fiber reinforced plastic and PCB micro-drilling, etc.

【Product Details】

1. Using formula, the hardness can reach 91.5 degrees, and the performance is excellent, so that the sharpening effect is fast and sharp;

2. The surface is treated with fine craftsmanship to enhance the image of the sharpener;

3. Suitable for fast and fine grinding of kitchen knives, fruit knives, etc.

【Features】

1. Simple and convenient, long life time, no rust, clean and sanitary, no water is needed, and the blade can be extremely sharp in just a few seconds.

2. The single-sided sharpening is converted to double-sided sharpening, which fundamentally changes the method, angle and efficiency of sharpening.

3. Support mirror effect processing.

4. Various shapes can be customized, such as trapezoidal sharpening blades, triangular sharpening blades, and support customized drawings.

5. Suitable for all kinds of kitchen knives, outdoor knives, scissors, Damascus knives and ceramic knives and other knives sharpeners

![]()

![]()

products profile

![]()

![]()

![]()

![]()

Tungsten carbide strips description

1, the purity of more than 99.95% of raw materials, impurities, less physical properties of the plate more stable;

2, the use of spray drying technology, the material in the fully sealed conditions using high purity nitrogen protection, effectively reduce the mixing process in the preparation of the possibility of oxygen, better purity, the material is not easy to dirty;

3, the density of the plate uniform: 300Mpa isostatic pressing machine to suppress, effectively prevent the production of defects, the plate density is more uniform;

Tungsten Carbide Strips Aplication and Characteristics

| GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

Plates Packing

![]()

Web:www.goldswordcarbide.com