100% Non Magnetic Tungsten Carbide Strips YN10 YN15 YN10X YN6

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | kilogramme/pcs |

| Packaging Details: | paper boxes, wooden boxes、carton,Iron barrel |

| Delivery Time: | 15~20 days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, T/T, Western Union |

| Supply Ability: | 50000pcs/month |

|

Detail Information |

|||

| Color: | Silver-grey,blank For Carbide Flat,Grey | Shape: | Tungsten Carbide Strip,Tungsten Carbide Round Rod |

|---|---|---|---|

| Characteristic: | 100%Non-magnetic,Magnetic Detection | Grade: | YN10X,YN15,YN06 |

| Product Name: | Non-magnetic Carbide | Application: | Non-magnetic Materials, Molds Used For Magnetic Field Press Molding, Corrosion-resistant Tools. |

| Chemical Composition: | WC+Ni | ||

| High Light: | Non Magnetic Tungsten Carbide Strips,100% Tungsten Carbide Strips,Tungsten Carbide Strips YN10 |

||

Product Description

YN10/YN15/YN10X/YN6 Non-magnetic strip,Used to make electronic non-device non-magnetic molds, etc.

Non-magnetic alloys refer to cemented carbide materials that are not magnetic or weakly magnetic. The development and production of non-magnetic cemented carbide materials is a significant performance of new cemented carbide materials with excellent non-magnetic properties. Continue to the final product, but the degree of difference depends on the amount and form of residual chlorine. Nowadays, non-magnetic cemented carbide is used. At this stage, the structure and phase composition of tungsten steel change with different cooling conditions. This feature can be used to heat tungsten steel to improve its physical and mechanical properties. Replacing non-magnetic steel with its excellent performance can double the work efficiency. With the development of social economy and the improvement of cemented carbide science and technology, the use of non-magnetic alloys will become more and more widespread.

2. Parameters

Hardness: 92.5

Flexural strength: 3240

Extension: 1770

Compressive strength: 4510

Impact resistance: 20

Uses: Non-magnetic materials, molds used for magnetic field press molding, and corrosion-resistant tools.

3. Material

The manufactured material must have high high temperature hardness and wear resistance, necessary bending strength, impact toughness and chemical inertness, good manufacturability (cutting, forging, heat treatment, etc.), and not easy to deform.

Generally, when the material hardness is high, the wear resistance is also high; when the bending strength is high, the impact toughness is also high. But the higher the material hardness, the lower its bending strength and impact toughness. High-speed steel is still a widely used material because of its high bending strength, impact toughness, and good machinability, followed by cemented carbide.

Polycrystalline cubic boron nitride is suitable for cutting high hardness hardened steel and hard cast iron, etc.; polycrystalline diamond is suitable for cutting non-ferrous metals, alloys, plastics and glass steel, etc.; carbon tool steel and alloy tool steel are currently only used For files, dies, taps and other tools.

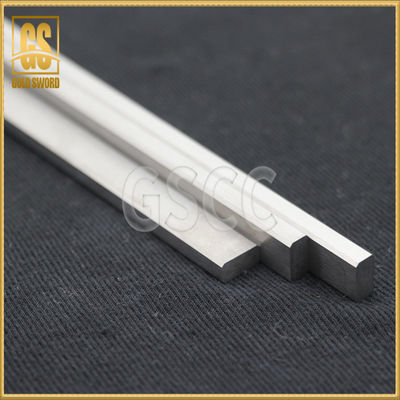

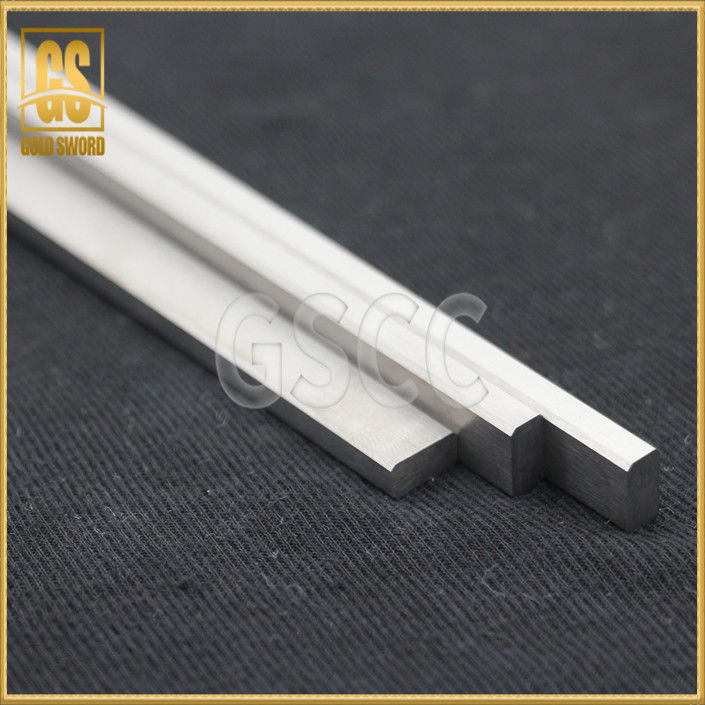

Non-magnetic strip display

![]()

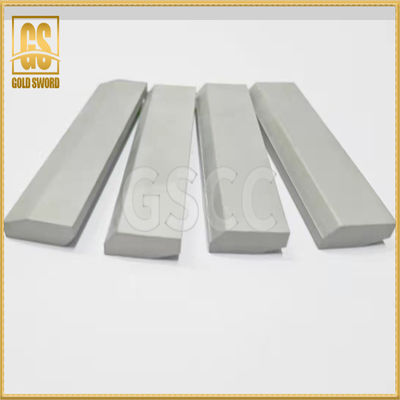

Non-magnetic round rods display

![]()

Non-magnetic products production process

![]()

Equipment Exhibition

![]()

Testing Equipment

![]()

![]()