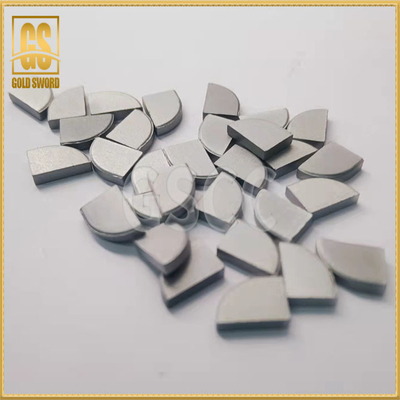

A320 Tungsten Carbide Cutting Tips YG8 YW2 YG15 YT15 YT5 YG20 4160511

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1kg |

|---|---|

| Price: | kilogramme/pcs |

| Packaging Details: | paper boxes, wooden boxes、carton,Iron barrel |

| Delivery Time: | 15~20 days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, T/T, Western Union |

| Supply Ability: | 10000pcs/month |

|

Detail Information |

|||

| Size:: | A208,A210,A310, A406, Can Be Cusotmized. | Application:: | Lathe Turning,brazing Turing |

|---|---|---|---|

| Material:: | Tungsten Carbide | Commodity Name:: | Cemented Carbide Products |

| Surface: | Sand-blasted Finished Or Gound | Classify: | Mill Cutter Tool |

| C For Turning Inserts: | Equilateral Triangular Inserts,IC 13mm,Edge Radius 0.3mm,C Chipbreaker | ||

| High Light: | A320 Tungsten Carbide Cutting Tips,YG8 Tungsten Carbide Cutting Tips,4160511 Tungsten Carbide Blade |

||

Product Description

Tungsten Carbide Cutting Brazing Tips,YG8/YW2/YG15/YT15/YT5/YG20 A320 4160511 Brazing Blade

Carbide turning tools are welded with carbide inserts and carbon steel shanks, which have high hardness, wear resistance and heat resistance.

Cemented carbide inserts are made of high wear-resistant and high-heat-resistant WC (tungsten carbide), TiC (titanium carbide), TaC (tantalum carbide) and Co (cobalt) powders sintered at high temperature. Check the official website of the knife.

1) Tungsten Cobalt (WC+Co) Blades

Tungsten-cobalt inserts, domestic nominal YG type, corresponding international nominal K type, these alloy inserts are used to process ferrous metals, non-ferrous metals and non-metallic materials that produce short chips, such as cast iron, aluminum alloy, copper alloy, plastic , Hard bakelite, etc. Commonly used grades are YG3, YG6, YG8, etc.

2) Tungsten-titanium-cobalt (WC+TiC+Co) blades

Tungsten-titanium-cobalt blades, the domestic nominal YT type, and the corresponding international nominal P type alloy blades are used to process metal materials that produce long chips, such as steel, cast steel, malleable cast iron, stainless steel, heat-resistant steel, etc. Commonly used grades are YT5, YT15, YT30, etc.

3) Tungsten-titanium-tantalum-cobalt (WC+TiC+TaC+co) blades

Tungsten-titanium-tantalum-cobalt inserts, national standard YW class, corresponding to international nominal M class, these alloy inserts are used to process ferrous or non-ferrous metals that produce long chips and short chips, such as steel, cast steel, austenitic stainless steel, resistant Hot steel, malleable cast iron, alloy cast iron, etc.

3. Diamond (PCD) turning tool

Diamond turning tools mainly process non-ferrous metals and non-metallic materials that require high finish such as copper, aluminum, zinc, alloys, plastics, rubber, bakelite, etc. Diamond turning tools have high finish and high wear resistance.

4. Cubic Boron Nitride (PCBN)

The cubic boron nitride turning tool mainly processes ferrous metals with high hardness such as quenched steel and iron-based powder metallurgy. This turning tool is characterized by high hardness and high wear resistance.

5. CNC turning tool (indexable turning tool)

CNC turning tools are mainly used for a type of turning tools on CNC machine tools. exchange sex,

3 Comments Share Report

![]()

![]()

| GRADE | ISO | DENSITY | HARDNESS | TRS | Applications recommended |

| GRADE | (g/cm3) | (HRA) | (N/mm2) | ||

| YG3 | K05 | 15.1 | 92 | 1400 | Suitable for finishing of cast iron and nonferrous metal. |

| YG6X | K10 | 14.95 | 91.5 | 1800 | The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

| YG6 | K15 | 14.95 | 90.5 | 1900 | Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG8 | K20 | 14.8 | 89.5 | 2200 | |

| YW1 | M10 | 13.1 | 91.6 | 1600 | Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

| W2 | M20 | 13 | 90.6 | 1800 | The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

| YT15 | P10 | 11.4 | 91.5 | 1600 | Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

| YT14 | P20 | 11.6 | 90.8 | 1700 | Suitable for the finishing and semi-finishing of steel and cast steel. |

| YT5 | P30 | 12.9 | 90.5 | 2200 | Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

YG3: suitable for finishing of cast iron and non-ferrous metals

YG6X, YG6A: suitable for finishing and semi-finishing of cast iron and non-ferrous metals, as well as for manganese steel and hardened steel.

YG6, YG8: suitable for rough machining of cast iron and light alloy, and also for milling of cast iron and low alloy steel

YW1, YW3, YW4: suitable for finishing and semi-finishing of stainless steel and common alloy steel

YW2: suitable for semi-finishing of stainless steel and low-alloy steel, mainly used for the processing of train tires

YT15, YT05: suitable for finishing and semi-finishing of steel and cast steel, medium feed and high cutting speed should be used

YT14, YS25: suitable for finishing and semi-finishing of steel and cast steel, medium feed should be used, YS25 is specially used for steel, cast steel milling speed

YT5: suitable for steel, cast steel.

![]()

![]()

Application Instructions for Welded Inserts Carbide Inserts

1. Welded cutting tool structure should have sufficient rigidity

Sufficient rigidity is ensured by the maximum allowable dimensions and heat treatment of higher strength steel grades

2. Carbide inserts should be firmly fixed

Cemented carbide inserts should have a sufficient degree of reliability, which is guaranteed by the kerf and welding quality. Therefore, the shape of the insert groove should be selected according to the shape of the insert and the geometric parameters of the insert.