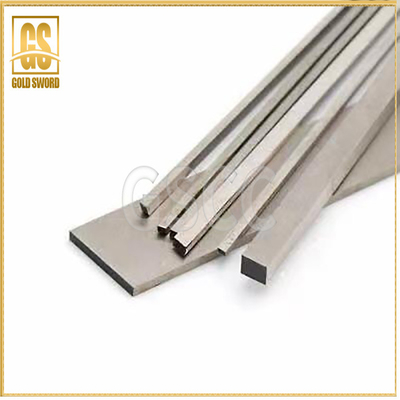

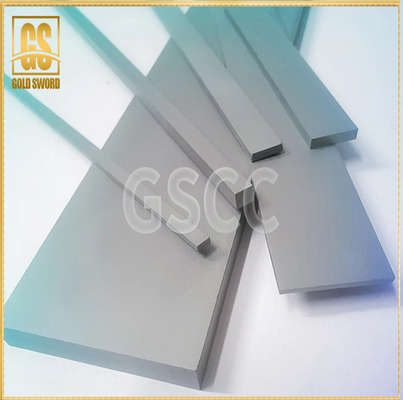

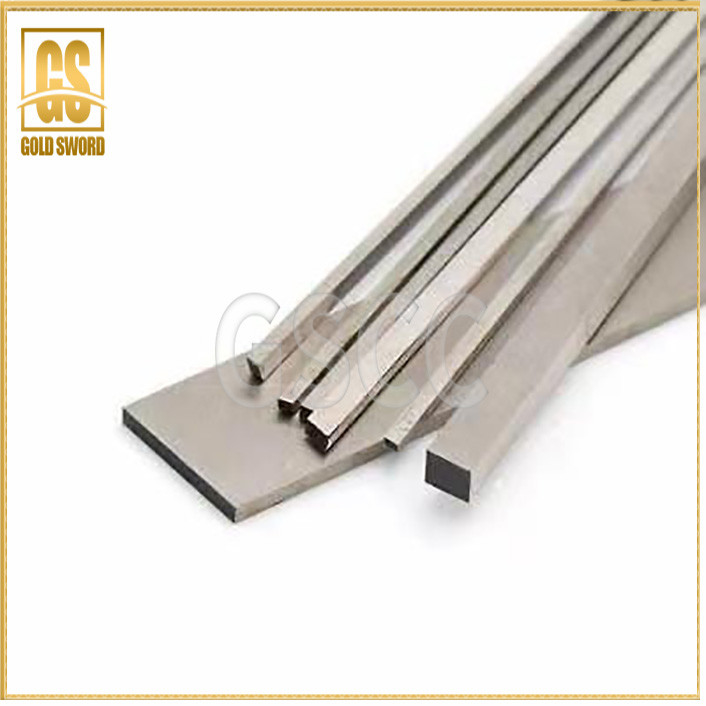

Non Standard Square Bar Cutting Tool For Agricultural Machinery

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Certification: | ISO9001 |

| Model Number: | Tungsten Carbide Square Bar |

Payment & Shipping Terms:

| Minimum Order Quantity: | negotiate |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Size:: | Customized, 3*6/10/30*330/320/310 | Feature: | High Precision |

|---|---|---|---|

| GS Grade: | RX10 / RX20 / RX10T / AB10 | Advantage: | Long Tool Life |

| Shape: | Tungsten Carbide Strip,Tungsten Carbide Square Bar | Tolerance: | 0~+-0.03mm ,Parallelism And Straightness 0~0.05mm For 600mm Long Strips |

| High Light: | RX10 Square Bar Cutting Tool,3x6 Square Bar Cutting Tool,Industrial Lithium Battery Processing Blades |

||

Product Description

Non-Standard Square Bar Cutting Tool For Agricultural Machinery Or Industrial Lithium Battery Processing Blades

Tungsten Carbide Square Bar Application:

Tungsten carbide strips is mainly used for making tools for wood cutting, like general wood, hard wood and some kind of soft wood. They also can be used for as wear parts with its high hardness and long life time. Using 100% tungsten carbide raw material, advanced technology, automatic pressing and HIP sintering. OEM and ODM are accepted, accepted non-standard square bar for processing and cutting

Tungsten Carbide Square Bar Characters and advantages

1 all the cutting tools quality meet the ISO international standard.

2 high strength and high hardness, hard-wearing

3 high productivity,more flatter.

4 high precision,Parallelism and straightness 0~0.05mm

5 long tool life,Several times longer life than ordinary HSS.

6 broad application area,for example:Agricultural machinery processing tools, industrial lithium battery processing blades

About Tungsten Carbide Square Bar :

The main composition of tungsten carbide bars or Hard Alloy Strips is tungsten carbide powders and cobalt powders .With its wear resistant and corrosion resistant ability , tungsten carbide nowadays is widely used in many areas such as : cutting tools , moulds , oil and automobile industry etc .

Tungsten carbide strip and bars is used as the cutter for the TCT woodworking knives for cutting all kinds of original wood , hard wood , HDF, MDF , plywood , particle board , laminated board, composite material ,grass, aluminum and metals . It can give much more excellent performance than HSS .

Cemented carbide strips are mainly made of WC tungsten carbide and Co cobalt powder mixed by metallurgical method through powder making, ball milling, pressing and sintering. The main alloy components are WC and Co. The content of WC and Co in the carbide strips used for different purposes is different, and the application range is very wide.

Note: Our company can produce alloy grades that are more suitable for special processing fields according to customer needs.

| GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

|

THICKNESS |

WIDTH |

LENGTH |

|||

| Size | Tolerance | Size | Tolerance | Size | Tolerance |

| 1~3 | 0~+0.3 | 4~6 | 0~+0.2 | 5~30 | 0~+0.5 |

| 3~5 | 0~+0.4 | 6~10 | 0~+0.3 | 30~60 | 0~+1 |

| 5~8 | 0~+0.5 | 10~15 | 0~+0.4 | 60~100 | 0~+1.5 |

| 8~12 | 0~+0.8 | 15~20 | 0~+0.5 | 100-150 | 0~+2 |

| 12~15 | 0~+1 | 20~25 | 0~+0.8 | 150~200 | 0~+2.5 |

| >15 | 0~+1.2 | 25~30 | 0~+1 | 200~250 | 0~+3 |

| 30~40 | 0~+1.5 | 250~300 | 0~+4 | ||

| 40~50 | 0~+2 | 300~350 | 0~+5 | ||

| 50~80 | 0~+3 | 350~450 | 0~+8 | ||

| >80 | 0~+5 | >450 | 0~+10 | ||

|

1,The deformation amount of the plane of ordinary specifications is no more than 0.3mm, and that of the side is no more than 0.5mm

|

|||||

|

2,Thickness <2MM, width BBB 0 20MM, lateral deformation less than or equal to 1MM

|

|||||

FAQ

Q: Do you set an MOQ and any discounts could be offered?

A: Don't worry! We don't have an MOQ and no matter how many you want to order is ok with us. But more quantity with more discount.

Q: Can this kind of products be customized?

A: Yes, we offer custom-made service for our clients. You just need to provide us some technical data such as dimensions.

Q: How long will you deliver the goods after I place an order?

A: We will send the items within 7 days once your payment is completed. We do not guarantee delivery time on all international shipments due to differences in customs clearing times in individual countries, which may affect how quickly your products is inspected.

Q: What's the warranty of the products?

A: If any quality problems on our side occured in this period, we will take on the shipping cost and replacement.

Q: How can I choose a shipping method?

A: For small quantities, express of DHL/UPS/Fedex door to door service is the best; for bulk quantities, shipping by sea is the best but takes too much time. For urgent orders, we suggest shipping by Air to airport.

![]()

![]()

![]()

![]()

![]()

![]()

![]()