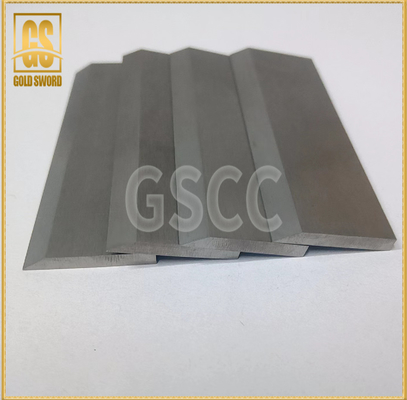

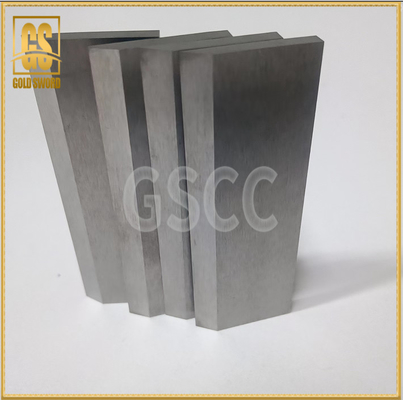

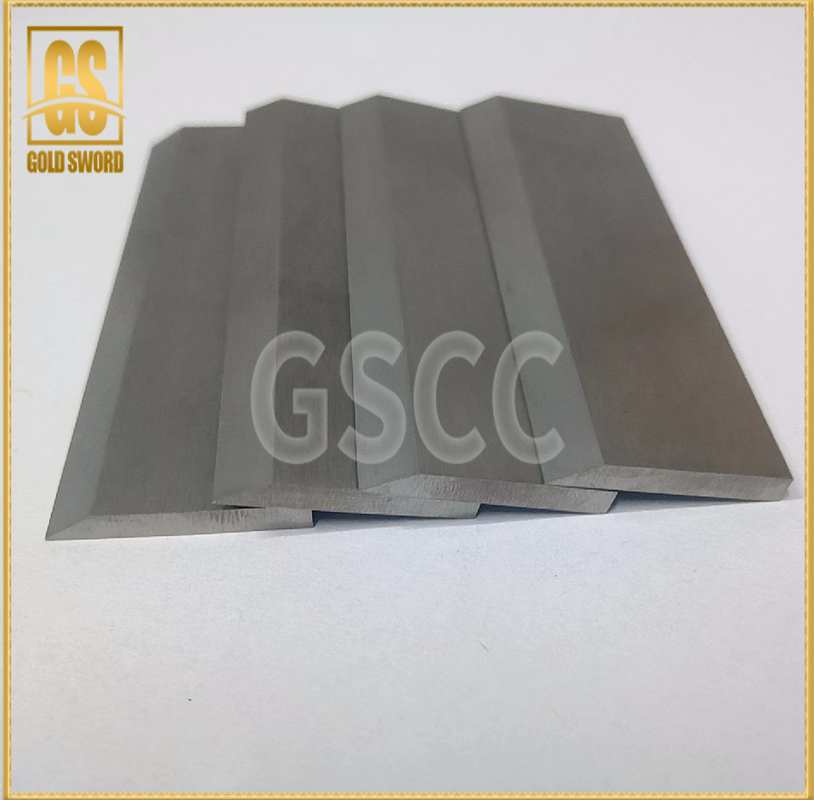

High Precision Finish Custom Tungsten Carbide Blade For Cutting Plastic Paper Textile

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | pcs |

| Packaging Details: | paper boxes, wooden boxes、carton,Iron barrel |

| Delivery Time: | 15-30 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000pcs/month |

|

Detail Information |

|||

| Features: | Excellent Wear Resistant And High Hardness,long Lasting Use,sharp Point | Surface: | Blanks Ungrounded/ground/grinded/polished Or As Requirment,coated (as Required) |

|---|---|---|---|

| Shape: | Customized,Various Shapes,Rectangle Inner Hole Blade | Advantage: | Durable,factory,30 Years Experience,Customer-customized Finishing Blades Can Quickly Formulate Product Plans Based On Customer Processing Conditions And Requirements, With Fast Quotation, High Precision, And Fast Processing. |

| Packing: | Brown Paper Box,customized,Plastic Box+Wood Carto | Oem: | Available,logo Laser Print |

| Usage: | Cutting Paper,plastic, Textile,etc | Tolerande: | 0~+0.05 |

| High Light: | HRA92 Tungsten Carbide Blade,Textile Cutting Tungsten Carbide Blade |

||

Product Description

High-Finish Products Provide High-Quality Blades And Parts For Cutting Plastic, Aluminum, Paper, Textiles, Etc.

Cemented carbide is a kind of alloy material made of hard compound of refractory metal and bonding metal by powder metallurgy process.

Hard alloy has high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance, even at 500℃ temperature is basically unchanged, at 1000℃ still has a high hardness.

Hard alloy is widely used as tool materials, such as turning tool, milling tool, planer, drill, boring tool, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and ordinary steel, can also be used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult to process materials.

![]()

1. Strong R&D team. Professional engineers serve for clients, recommend products and grades as per your applications. We also offer after-sale service.

2. Strong Mould R&D team. We support product customization as per specific requirements, ensure high working efficiency with good product quality.

3. Successful cooperation case: We cooperate with clients in domestic and abroad, and get good feedback from them.

4. Customer-customized finishing blades can quickly formulate product plans based on customer processing conditions and requirements, with fast quotation, high precision, and fast processing.

![]()

Product Description

Virgin Tungsten Carbide Die Moulds

virgin Tungsten Carbide Die moulds for drawing brass&steel material YG6/YG8

Tungsten Carbide Square Bar Application:

Tungsten carbide strips is mainly used for making tools for wood cutting, like general wood, hard wood and some kind of soft wood. They also can be used for as wear parts with its high hardness and long life time. Using 100% tungsten carbide raw material, advanced technology, automatic pressing and HIP sintering. OEM and ODM are accepted.

Tungsten Carbide Square Bar Characters and advantages

1 broad application area

2 high productivity

3 high precision

4 long tool life

5 all the cutting tools quality meet the ISO international standard.

6 high strength and high hardness, hard-wearing

![]()

| GRADE | ISO | DENSITY | HARDNESS | TRS | Applications recommended |

| GRADE | (g/cm3) | (HRA) | (N/mm2) | ||

| YG3 | K05 | 15.1 | 92 | 1400 | Suitable for finishing of cast iron and nonferrous metal. |

| YG6X | K10 | 14.95 | 91.5 | 1800 | The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

| YG6 | K15 | 14.95 | 90.5 | 1900 | Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG8 | K20 | 14.8 | 89.5 | 2200 | |

| YW1 | M10 | 13.1 | 91.6 | 1600 | Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

| W2 | M20 | 13 | 90.6 | 1800 | The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

| YT15 | P10 | 11.4 | 91.5 | 1600 | Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

| YT14 | P20 | 11.6 | 90.8 | 1700 | Suitable for the finishing and semi-finishing of steel and cast steel. |

| YT5 | P30 | 12.9 | 90.5 | 2200 | Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()