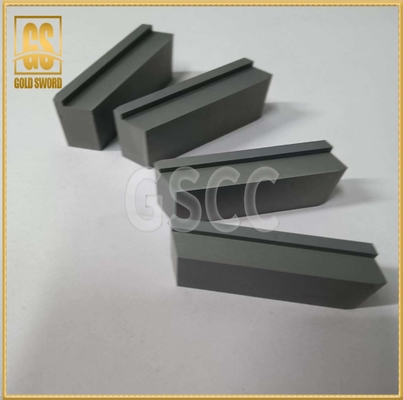

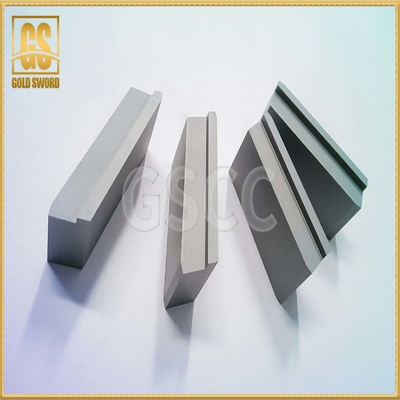

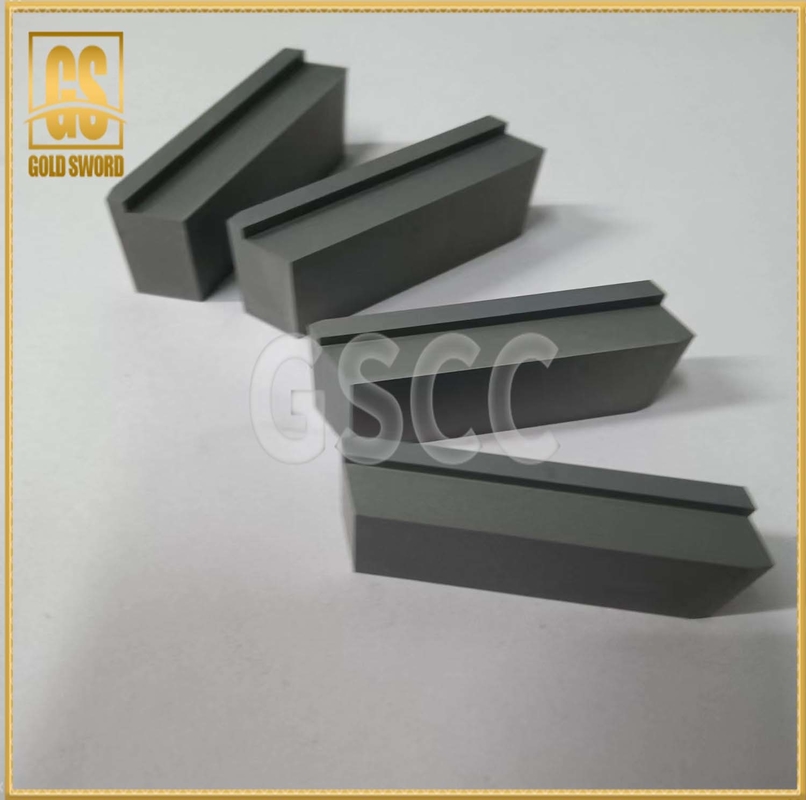

High Gloss Tungsten Aliform Slotted Chamfer Targeted Mechanical Specific Blade

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | kilogramme or pcs |

| Packaging Details: | boxes, carton |

| Delivery Time: | 15-30 days |

| Payment Terms: | Western Union, MoneyGram |

| Supply Ability: | 30000pcs/ton |

|

Detail Information |

|||

| Type: | Power Tool Parts,High Wear Resistance,Hand Tool Parts,any Types Are Avaliable | Material: | 100% Virgin Tungsten Carbide,100% Virgin Raw Material,Tungsten Carbide WC+Co,WC+CO Good Raw Material,WC+CO |

|---|---|---|---|

| Application: | Processing Original Wood,Metal Wood Cutting,solid Wood,for Woodworking Cutting Tools Or Used To Be Wear Part Etc.,End Mill.cutting Tools | Grade: | K30,K20,YG8,We Can Recommend Based On Your Application |

| Product Name: | Left And Right Machetes,edge Cutting Blade. | Surface: | Polished,Uncoated,Blanks Or Polished Grinding,Blank(Unground) |

| Advantage: | High Wear Resistance,More Than 20 Years Experience,Smooth And Straight Cut,Excellent Wear Resistance And Hardness,Competitive | Name: | Cemented Carbide Square Yg8 Flat Bar/strips K10&k20 Carbide Bar/strips,Cemented Carbide Strips,Tungsen Carbide Strips |

| Service: | ODM OEM,OEM&ODM | Color: | Silver-grey,blank For Carbide Flat,Grey,silver |

| Feature: | High Performance Cutting,Wear Resistance | Hardness: | HRA89-HRA92.9 |

| Grain Size: | Fine; Medium,sub Micro Size,0.8-6.0um | Shape: | Line Cutting Slot,Left And Right Machetes,Customized,Long Side Oblique Angle Long Bilateral Diagonal |

| Trs: | 2200- 4000 N/mm3 | ||

| High Light: | Tungsten Aliform Slotted Chamfer,K30 Tungsten Aliform Slotted Chamfer,ISO9001 Targeted Tungsten Cutting Tools |

||

Product Description

High Gloss Tungsten Non Standard Aliform slotted chamfer, targeted mechanical specific blade

zhou Gold Sword Cemented Carbide Co., Ltd. Located In Zhuzhou City, Hunan Province, Which Is The Largest Cemented Carbide Production And Sales Base In China. Our Main Products Are Carbide Strips, Carbide STB Bars, Carbide Sand Breaking Strips, Carbide ASA Brazing Tips, Carbide Cold Heading Dies And Carbide Rods. Our Professional And Technical Personnel All Have Above 15 Years Of Cemented Carbide Production Experience, The Rich Experience Can Provide Our Customers Of High-Quality Products And Thoughtful Technical Support, And Continuous Improvement To Meet Customer Needs.

The "stability" and "consistency" of products are the focus of our quality control.

First of all, we have advanced equipment, such as spray tower, Solid furnace , isostatic static pressure punching machine.

We select raw material which is exclusive manufacturer.We make sure we have enough stock,all sizes of strips and types are complete,To ensure the capacity have a monthly output of 5 tons.The company uses advanced testing equipment to continuously formulate and improve the quality control system.

Strictly train a quality control technician with outstanding skills,

According to the raw material monitoring, process production and final inspection,

The whole process is strictly monitored in accordance with international quality control system standards;

All-round inspection of products from chemical composition, organization structure, physical properties, appearance size, etc.

Adopt dedicated full-time responsibility system to achieve professional services,when we find problems timely feedback, prompt delivery and solve processing problems quickly.

We have been rooted in the cemented carbide industry and have served foreign trade companies in the Zhuzhou industry for many years. Our customers are mainly metal processing, woodworking and textile tools, petroleum machinery, etc., and are well received by customers.

Based on the damands of customers , for different industries, different materials and different working conditions, provide customers with accurate service and solutions of products, and provide high cost-effective products, to keep the promises of our customers, and Timely provide the professional technical services.

Application scope of tungsten steel blade:

1. Used to make blanking dies. High-speed die and multi-station progressive die used for blanking copper, aluminum, stainless steel, cold-rolled sheet, EI sheet, Q195, SPCC, silicon steel sheet, hardware, standard parts, upper and lower punches, etc.

2. Used to make knives. Such as woodworking industry knives, plastic crushing knives and so on.

3. For making high temperature resistant parts, etc. Such as the guide rail of the machine tool, the anti-theft reinforcement board of the automatic teller machine, etc.

4. Used to make chemical industry parts.

5. The material properties of cemented carbide sheets for different purposes are not consistent. When using, a cemented carbide sheet of suitable material should be selected according to the application.

Non-standard Tungsten carbide blade description

1, the purity of more than 99.95% of raw materials, impurities, less physical properties of the plate more stable;

2, the use of spray drying technology, the material in the fully sealed conditions using high purity nitrogen protection, effectively reduce the mixing process in the preparation of the possibility of oxygen, better purity, the material is not easy to dirty;

3, the density of the plate uniform: 300Mpa isostatic pressing machine to suppress, effectively prevent the production of defects, the plate density is more uniform;

![]()

![]()

![]()

![]()

![]()

![]()

![]()

The production of special components

1. Provide solutions or design blades through the customer's work scenarios.

2. What kind of processing process is used to design and locate the blade according to the customer's specific machine.

3. The blank production generally adopts spray granulation, and the overpressure sintering process ensures the internal structure of the product. Processing generally uses wire cutting, a variety of mechanical grinding machine, to ensure the tolerance and accuracy.

Web:www.goldswordcarbide.com