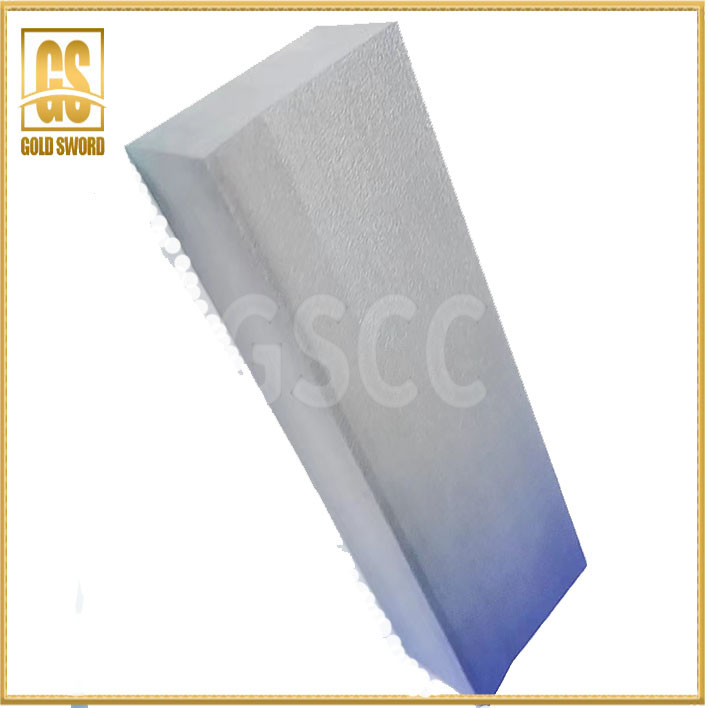

Polished Carbide Wear Strips with Tensile Strength 1800-2100 MPa

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiatial |

| Packaging Details: | paper boxes, wooden boxes、carton,Iron barrel |

| Delivery Time: | 15~20 days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, T/T, Western Union |

| Supply Ability: | 50000pcs/month |

|

Detail Information |

|||

| Thermal Expansion Coefficient: | 4.5-5.5×10-6/K | Shape: | Strip |

|---|---|---|---|

| Thermal Conductivity: | 90-110 W/m·K | Bending Strength: | 2500-3000 MPa |

| Material: | Tungsten Carbide | Surface Finish: | Polished |

| Density: | 14.9-15.1 G/cm3 | Surface Roughness: | Ra 0.4 |

| High Light: | Polished Carbide Wear Strips,2100 MPa Carbide Wear Strips,Wear Resistant Polished Carbide Strips |

||

Product Description

Product Description:

Tungsten Carbide Strips are widely used as cutting tools and wear strips in many industrial applications. These carbide strips are made of tungsten and have excellent hardness, wear resistance and thermal conductivity, ranging from 90 to 110 W/m·K. The surface of the strips is highly polished to ensure a smooth finish and further improve the wear resistance.

The shape of the strips is designed to provide a precise and accurate cutting performance. The strips are available in various sizes and thicknesses to meet the needs of different applications. The tungsten carbide strips are especially suitable for cutting tools, wear strips and other industries.

The tungsten carbide strips offer a high level of durability and performance due to their excellent hardness and wear resistance. Their polished surface makes them perfect for various industrial applications, such as cutting tools, wear strips and more. With their superior thermal conductivity, they are able to maintain their shape and performance for a longer period of time.

Tungsten Carbide Strips are the perfect choice for cutting tools and wear strips. They are designed for precise and accurate cutting performance and offer excellent hardness, wear resistance and thermal conductivity. With their polished surface and various sizes and thicknesses, these tungsten carbide strips are the ideal choice for many industrial applications.

Features:

- Product Name: Tungsten Carbide Strips

- Hardness: HRA 91.5-92.5

- Size: Customized

- Thermal Expansion Coefficient: 4.5-5.5×10-6/K

- Surface Roughness: Ra 0.4

- Fracture Toughness: 9-11 MPa·m1/2

- Ideal for carbide wear strips, tungsten strips, Tungsten Carbide Strips applications

Technical Parameters:

| Parameters | Values |

|---|---|

| Compressive Strength | 4000–4500 MPa |

| Surface Finish | Polished |

| Hardness | HRA 91.5–92.5 |

| Surface Roughness | Ra 0.4 |

| Thermal Expansion Coefficient | 4.5–5.5×10-6/K |

| Fracture Toughness | 9–11 MPa·m1/2 |

| Thermal Conductivity | 90–110 W/m·K |

| Color | Silver Gray |

| Bending Strength | 2500–3000 MPa |

| Size | Customized |

Applications:

Gold sword tungsten carbide wear strips are widely used in various industries. They are made of tungsten carbide material, with excellent fracture toughness, thermal conductivity, surface roughness and bending strength, ranging from 9-11 MPa·m1/2, 90-110 W/m·K, Ra 0.4 to 2500-3000 MPa respectively. The Model Number can be customized, and the Minimum Order Quantity is 1pcs. The Price is Negotiatial, and the Packaging Details are paper boxes, wooden boxes, carton, Iron barrel. The Delivery Time is 15~20 days, and the Payment Terms are L/C, D/A, D/P, D/P, T/T, T/T, Western Union. The Supply Ability is 50000pcs/month, and the Shape is Strip.

The Gold Sword tungsten carbide wear strips are mainly used in metal stamping, printing, papermaking, mining, woodworking, and other industrial fields. They provide superior wear resistance to metal parts, and can be used to make various cutting tools, punches, punches, etc. They are also widely used in non-ferrous metal stamping, cutting tools for industries such as aerospace, automotive, and medical. The tungsten carbide wear strips can provide excellent wear resistance and durability, thus greatly improving the working efficiency of the industrial equipment.

Packing and Shipping:

Tungsten carbide strips are usually packaged in a sealed plastic container or bag. The package should be clearly marked with the product description, weight, and dimensions. Packages should also be clearly labeled with the product name, manufacturer, and any other relevant information.

Tungsten carbide strips should be shipped on pallets with proper wrapping and cushioning. The pallets should be secured and should not shift during transit. Proper shipping labels should be applied to the package, including the shipping address and the carrier’s contact information.