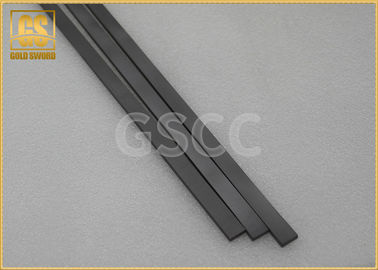

Long Usage Lifetime Tungsten Carbide Bar Stock Fine Thermal Shock Resistance

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Model Number: | Tungsten Carbide Bar Stock |

Payment & Shipping Terms:

| Minimum Order Quantity: | negotiate |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Bar Stock | Surface: | Polished |

|---|---|---|---|

| Life: | Long Usage Lifetime | Feature: | Fine Thermal Shock Resistance |

| Highlight: | tungsten carbide rod blanks,cemented carbide rods |

||

Product Description

Long Usage Lifetime Tungsten Carbide Bar Stock Fine Thermal Shock Resistance

Tungsten Carbide Bar Stock Description:

Tungsten Carbide round rod is a tungsten steel round rod.In simple terms, a tungsten steel round rod or a hard alloy round rod.Tungsten carbide round bar/rod has high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance. Even at 500 ℃ temperature, itself is basicly remains the same. There are still very high hardness at 1000 ℃.

Traditional tool grades and usage recommendations

| Iso classification grouping code | Mark |

Density |

Hardness |

Bending strength |

use |

| K01 | YD05 | 14.90 | 93.0 | 1600 | It is specially used for processing various nickel-based, cobalt-based, iron-based and tungsten carbide-containing self-fluxing spray alloy materials, and can also be used for the processing of hardened steel. |

| K05 | YG3X | 15.10 | 91.8 | 1600 | Suitable for finishing, fine boring of cast iron, non-ferrous metal, heat resistant alloy and titanium alloy. |

| K10 | YD101 | 14.95 | 92.1 | 2500 | It has excellent wear resistance and toughness. It is used for finishing and finishing of non-ferrous metals and cast irons, especially for the processing of aluminum and its alloys. Turning is suitable for medium and high speed, and medium speed is recommended for milling. |

| YG6X | 14.95 | 91.5 | 2300 | Suitable for finishing of cast iron, non-ferrous metals, heat-resistant alloys and titanium alloys. | |

| K20 | YD201 | 14.89 | 91.0 | 2500 | Suitable for roughing to semi-finishing of heat resistant alloys and titanium alloys, cast iron and aluminum alloys. |

| YG6 | 14.95 | 89.5 | 2000 | Suitable for semi-finishing and light-load roughing of cast iron, non-ferrous metals and their alloys, heat-resistant alloys, titanium alloys and non-metallic materials. | |

| YG8 | 14.75 | 89.0 | 2200 | It is suitable for roughing of cast iron, non-ferrous metals and their alloys, heat-resistant alloys and titanium alloys. It has high impact resistance and is suitable for continuous and interrupted cutting. | |

| M05 | YS8 | 13.90 | 92.5 | 1800 | It is suitable for the finishing of iron-based, nickel-based superalloys and high-strength steels. It is also suitable for the finishing of chilled cast iron, heat-resistant stainless steel, high-manganese steel, hardened steel and glass products. |

| M10 | YW1 | 13.0 | 91.5 | 1600 | Suitable for semi-finishing of stainless steel and common alloy steel. |

| YW3 | 12.9 | 92.0 | 1800 | Suitable for finishing and semi-finishing of stainless steel and common alloy steel. | |

| M20 | YS2T | 14.40 | 91.5 | 2500 | Suitable for finishing and semi-finishing of stainless steel and low alloy steels and iron-based alloys, as well as for integral milling of low alloy steels. |

| YW2 | 12.9 | 91.0 | 2000 | Suitable for finishing and semi-finishing and light-load roughing of stainless steel and alloy steel. | |

| M30 | YL10.2 | 14.50 | 92.0 | 2800 | Suitable for high temperature alloys, heat resistant alloys, titanium alloys, etc., especially for coarse and semi-finishing of aerospace materials, allowing intermittent turning with increased rake angle. |

| P10 | YC10 | 10.31 | 92.0 | 1600 | Suitable for finishing steel and cast steel, with cutting speed and low feed low depth. |

| P20 | YC201 | 11.79 | 91.8 | 1800 | Suitable for semi-finishing and light-load roughing of steel, cast iron and stainless steel, it is a universal mark with good applicability. |

| YS25 | 13.0 | 90.5 | 2200 | Specially used for rough milling of steel and cast steel. | |

| YT14 | 11.40 | 90.5 | 1800 | Specially used for semi-finishing of steel and cast steel. | |

| P40 | YC45 | 12.75 | 90.0 | 2550 |

Suitable for gravity cutting of steel and cast steel, it can be used for large cutting, also for section milling. |

Application of Tungsten Carbide Bar

1. Metal working,Blanks tungsten carbide plates for machinery lathe to machine HSS material,Alu ,steel,and stainless steel,etc.

2. Wood working,blanks and finished solid tungsten carbide plate for wood working stone pit industry and mining industry.

3. Stone working,blank and finished solid tungsten carbide plate for crusher machining of marble,granite,cobblestone,mountain stone,etc.

4. Other application,such as wear resistance parts of punching mold,measuring and cutting industry.