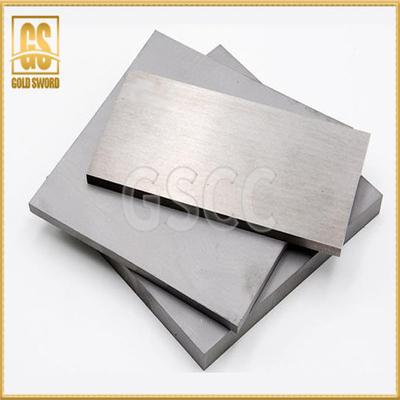

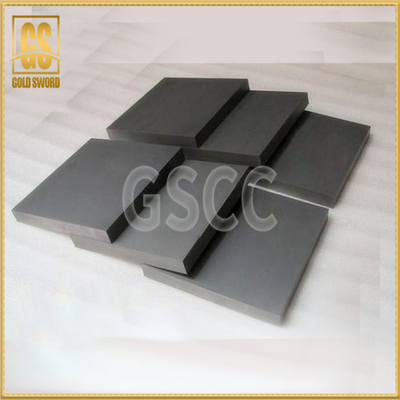

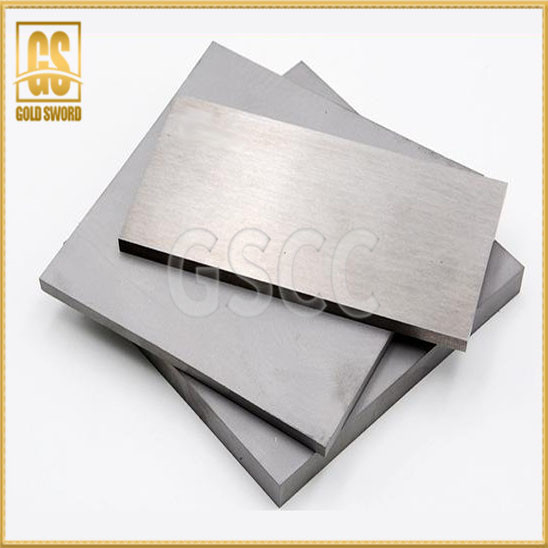

Customized Yg15 MD4 Steel Tungsten Carbide Sheet

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | 0.06×6×6 inch 80×40×20 mm |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1kg |

|---|---|

| Price: | kilogramme |

| Packaging Details: | boxes, carton |

| Delivery Time: | 15-30 days |

| Payment Terms: | FOB, L/C, T/T |

| Supply Ability: | 30000pcs/month |

|

Detail Information |

|||

| Type: | Power Tool Parts,High Wear Resistance | Material: | 100% Virgin Tungsten Carbide |

|---|---|---|---|

| Application: | For Woodworking Cutting Tools Or Used To Be Wear Part Etc. | Surface: | Polished |

| Size: | Customer's Request | Advantage: | High Wear Resistance,Excellent Wear Resistance And Hardness |

| Name: | Cemented Carbide Strips,Tungsen Carbide Strips | Service: | ODM OEM |

| Density: | 14.3-14.95g/cm3 | Hardness: | HRA87-HRA92.5 |

| Chemical Composition: | WC+CO | Tolerance: | Blank Flat Bend 0.3, Side Bend 0.3, Ground Parallel 0.01mm,flatness 0.01mm |

| High Light: | MD4 Steel Tungsten Carbide Sheet,Yg15 Tungsten Carbide Sheet,HRA92.5 Tungsten Steel Sheet |

||

Product Description

Factory sales can be customized according to specifications YG15 MD4 tungsten steel sheet carbide tungsten carbide sheet

Tungsten carbide plates, have high hardness, wear-resistance, and resistance to bending. They're widely used in cutting tool, crusher, wear parts, moulding base and other fields. We provide various size, such 154.2

*154.2mm*1.52mm, 20*20mm,50*50mm, 100*100mm, 200*200mm, and your customized sizes are welcomed.

Tungsten sheets can be used to make: electrodes, heat elements, heat shield, Boats for electronics, and vacuum furnace.

1. tungsten are mainly used in metallurgy industry, mechanism process industry and rare earth smelting industry;

2. They are more frequently used in crystalloid materials and other burgeoning high-tech industries;

3. The tungsten should be used in vacuum or deoxidize atmosphere and the highest using temperature should be no more than 2000ºC.

Application scope of tungsten steel sheet:

1. Used to make blanking dies. High-speed die and multi-station progressive die used for blanking copper, aluminum, stainless steel, cold-rolled sheet, EI sheet, Q195, SPCC, silicon steel sheet, hardware, standard parts, upper and lower punches, etc.

2. Used to make knives. Such as woodworking industry knives, plastic crushing knives and so on.

3. For making high temperature resistant parts, etc. Such as the guide rail of the machine tool, the anti-theft reinforcement board of the automatic teller machine, etc.

4. Used to make chemical industry parts.

5. The material properties of cemented carbide sheets for different purposes are not consistent. When using, a cemented carbide sheet of suitable material should be selected according to the application.

Tungsten carbide plate description

1, the purity of more than 99.95% of raw materials, impurities, less physical properties of the plate more stable;

2, the use of spray drying technology, the material in the fully sealed conditions using high purity nitrogen protection, effectively reduce the mixing process in the preparation of the possibility of oxygen, better purity, the material is not easy to dirty;

3, the density of the plate uniform: 300Mpa isostatic pressing machine to suppress, effectively prevent the production of defects, the plate density is more uniform;

Tungsten carbide plate Characteristics

1, the tungsten carbide plate with fine compactness, strength and hardness indicators are in line with the standard: the use of low-pressure sintering technology, so that the pores within the plate to be effectively eliminated, the quality is more stable.

2, the use of cryogenic treatment technology, so that the internal microstructure of the plate to be improved, the internal stress can be greatly reduced, effectively avoid the plate in the cutting process of the possibility of cracks generated;

products profile

![]()

![]()