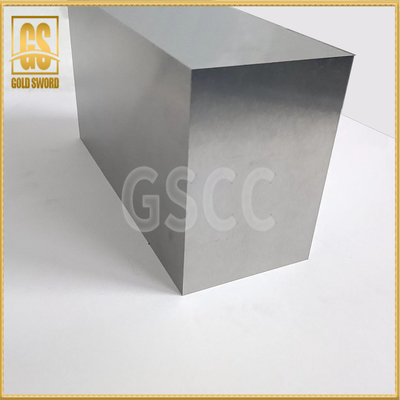

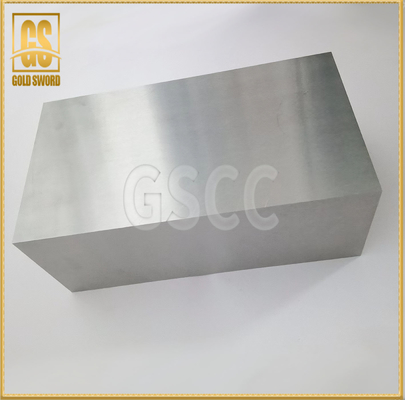

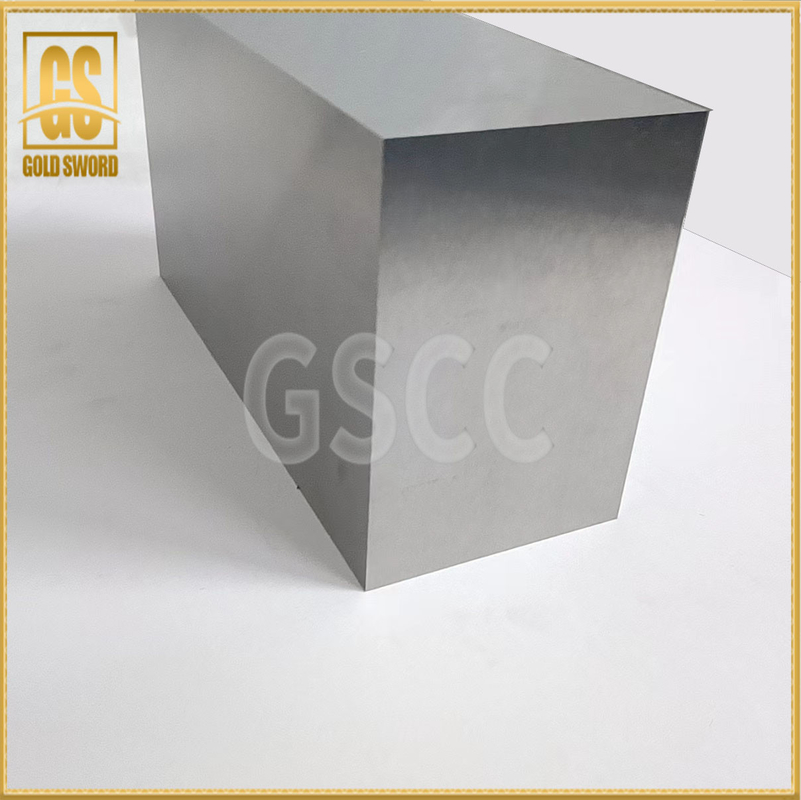

MD45A Grade Thick Tungsten Carbide Plate Tools High Toughness For Assembly Metal

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

| Certification: | ISO9001 |

| Model Number: | 160*80*90, 160*60*90 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT, L/C |

| Supply Ability: | 1000pcs/ton |

|

Detail Information |

|||

| Usage: | Assembly Tools | Material: | Tungsten Carbide, Cemented Carbide,carbide Steel. |

|---|---|---|---|

| Application: | Small Inserts, Cutting Tips, Wear Parts | Size: | Customized |

| Name: | Tungsten Carbide Sheet Metal | Width: | Custom |

| High Light: | Thick Tungsten Carbide Plate Tools,MD45A Grade Tungsten Carbide Plate,High Toughness Tungsten Carbide Sheet |

||

Product Description

MD45A Grade Carbide Thick Plate Tools For Assembly Metal With High Toughness

Features of tungsten carbide sheet:

1. The purity of the raw materials is more than 99.5%, the impurity content is very small, and the physical properties of the board are more stable;

2. Using spray drying technology, the materials are protected by high-purity nitrogen under fully sealed conditions, which effectively reduces the possibility of oxygenation during the preparation of the mixture, and the purity is better, and the materials are not easy to be dirty;

3. Uniform density of cemented carbide plates: it is pressed by a 300Mpa isostatic press, which effectively prevents the occurrence of pressing defects, and the density of the plate blanks is more uniform;

4. The compactness of the plate is excellent, and the strength and hardness indicators are excellent: the ship low-pressure sintering technology is used to effectively eliminate the pores in the plate and the quality is more stable.

5. Cryogenic treatment technology is used to improve the internal metallographic structure of the plate, and the internal stress can also be greatly eliminated, avoiding the occurrence of cracks in the cutting and forming process of the plate.

| GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

Carbide Wear Parts is a hard material composed of a metal matrix composite where carbide particles act as the aggregate and a metallic binder serves as the matrix. It is one of the most successful composite engineering materials ever produced. Its unique combination of strength, hardness and toughness satisfies the most demanding applications.

Tungsten carbide is used in machining tough materials such as cast iron or steel, as well as in situations where other tools would wear away, such as mining tools and wear parts. Most of the time, carbide will leave a better finish on the part,and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools.

![]()

![]()

Production process:

Pulverizing → formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → re-drying → sieving to obtain a mixture → granulating → pressing → forming → sintering → forming (blank) →Flaw inspection→Packing→Warehousing.

![]()

Tungsten carbide plate description

1, the purity of more than 99.95% of raw materials, impurities, less physical properties of the plate more stable;

2, the use of spray drying technology, the material in the fully sealed conditions using high purity nitrogen protection, effectively reduce the mixing process in the preparation of the possibility of oxygen, better purity, the material is not easy to dirty;

3, the density of the plate uniform: 300Mpa isostatic pressing machine to suppress, effectively prevent the production of defects, the plate density is more uniform;

Packing

![]()